Discover Reliability Matters

Reliability Matters

Reliability Matters

Author: Mike Konrad

Subscribed: 34Played: 1,292Subscribe

Share

© Copyright Mike Konrad

Description

Reliability Matters is a podcast on the subject of reliability of circuit assemblies. Reliability "best practices" and success stories are discussed. This podcast features interviews with experts in the electronic assembly industry.

All electronic production segments which effect product reliability are on the table. This includes contamination, coating, cleanliness assessment, inspection, building for harsh environments, reflow, printing, failure analysis, board fabrication, and much more.

Your Host:

Mike Konrad began his career in the electronic assembly equipment industry in 1985. Mike founded Aqueous Technologies in 1992 in response to the Montreal Protocol and the resulting international treaty banning most popular cleaning/defluxing solvents.

Mike is an internationally known speaker on the subject of increasing reliability through contamination removal and cleanliness quantification techniques and procedures. Mike was awarded “Distinguish Speaker Status” with SMTA in 2018 and received the “Rich Freiberger Best of Conference Award” in 2019.

Mike is a member of the SMTA Global Board of Directors where he is Vice President of Communications. Mike is also Vice President of Technical Programs for the Los Angeles / Orange County SMTA Chapter.

Visit the Reliability Matters Podcast Website:

https://www.reliabilitymatterspodcast.com

All electronic production segments which effect product reliability are on the table. This includes contamination, coating, cleanliness assessment, inspection, building for harsh environments, reflow, printing, failure analysis, board fabrication, and much more.

Your Host:

Mike Konrad began his career in the electronic assembly equipment industry in 1985. Mike founded Aqueous Technologies in 1992 in response to the Montreal Protocol and the resulting international treaty banning most popular cleaning/defluxing solvents.

Mike is an internationally known speaker on the subject of increasing reliability through contamination removal and cleanliness quantification techniques and procedures. Mike was awarded “Distinguish Speaker Status” with SMTA in 2018 and received the “Rich Freiberger Best of Conference Award” in 2019.

Mike is a member of the SMTA Global Board of Directors where he is Vice President of Communications. Mike is also Vice President of Technical Programs for the Los Angeles / Orange County SMTA Chapter.

Visit the Reliability Matters Podcast Website:

https://www.reliabilitymatterspodcast.com

183 Episodes

Reverse

This episode is all about SMTAI, surface mount Technology International, taking place OCTOBER 19 - 23, 2025 at the DONALD E. STEPHENS CONVENTION CENTER in ROSEMONT, ILLINOIS. SMTA International is the premier gathering for innovation and collaboration in electronics assembly, surface mount technology, and advanced manufacturing.This year, SMTAI is more than just a conference and expo. It’s an opportunity for experts, newcomers, industry leaders, and rising professionals to come together, exchange ideas, showcase breakthroughs, and shape the future of electronics manufacturing. Over several days, you’ll see deep-technical sessions, the latest research, hands-on exhibits, and, co-located with the assembly show, you can expect a bustling expo floor where solution providers and attendees connect on everything from process optimization to next-generation materials.To talk more about the technical conference, I’ve invited members of the conference committee to share some highlights of the conference.Tony Lentz from FCT AssemblyGayle Towell from Aim SolderTom Rovere from Lockheed MartinMaurice Dore from ValeoKelly Flanagan from RockwellAnd, although not a member of the Technical Committee but a member of the SMTA Global Board of Directors and Chair of the Students and Young Professionals committee, Dr. Adam Klett of Kyzen Corporation.More information on SMTAI is available here:https://www.smtai.org

In this episode, I’m joined by Chris Ward, founder and Managing Director of Solderking Assembly Materials Limited, a UK-based manufacturer of solders and chemical consumables for electronic, electrical, and engineered assemblies.Chris brings decades of experience in soldering materials and chemical formulations—and he’s built a company committed to performance, consistency, and innovation.Earlier this year, Chris and his company were honored with the prestigious King’s Award for Enterprise in International Trade, recognizing their exceptional export growth. That recognition earned him an invitation to Windsor Castle, where he had the distinct honor of meeting King Charles III.Today, we’ll explore the evolving world of soldering materials—from the realities behind “no-clean” flux, to reliability challenges in harsh environments, to innovations in solder chemistry that support today’s miniaturized and mission-critical electronics.Whether you're on the production floor, in the design lab, or managing quality and reliability, this is a conversation that brings valuable insight into the materials behind the mission.SolderKing:https://solderking.com

On this episode of Reliability Matters, we’re diving into a deceptively simple but incredibly important topic, humidity, and the massive impact it can have on electronic assembly reliability.Joining me is Viktoria Rawinski, a seasoned expert in materials science and reliability engineering, whose career spans decades of hands-on experience in failure analysis, process optimization, and design-for-reliability practices. Viktoria is not only a respected voice in the industry, but also a passionate educator, known for breaking down complex technical issues into actionable insights.In her two-part LinkedIn technical series, “Humidity – A Small Cause with a Huge Effect,” Viktoria explores how environmental moisture, often overlooked or underestimated, can trigger serious failure mechanisms in circuit assemblies, especially as devices become smaller and more complex. From solder mask absorption to electrochemical migration, we'll unpack the hidden risks that can jeopardize product performance and long-term reliability.Whether you're in design, manufacturing, or quality assurance, this is a conversation you won’t want to miss.Viktoria's Websitewww.rawinski.de

Today, I’m joined by two of the most respected names in the electronics manufacturing industry, Phil Zarrow and Jim Hall. Together, they bring decades of hands-on experience and unparalleled insight into the challenges and solutions within our field.Jim and Phil are the driving forces behind ITM Consulting, where they help manufacturers around the world improve processes, solve complex problems, and build more reliable products. Whether it’s soldering, cleaning, reflow profiling, process control, or failure analysis, these two have seen it all, fixed it all, and taught it all.In this episode, we tackle some of the most pressing issues facing the industry today, from the challenges of miniaturization, the reality of voiding, to the rise of electronics deployed into harsh environments, to IPC standards, and the role of process control in ensuring long-term reliability.Whether you're a process engineer, a quality manager, or simply passionate about electronics manufacturing, this is a conversation you won’t want to miss.ITM Consulting:https://itmconsulting.com

In this episode, we’re diving into a topic that’s rapidly reshaping our industry: Artificial Intelligence in PCB Design. Far from a futuristic concept, AI is already being integrated into advanced design tools—improving efficiency, reducing design iterations, and helping engineers tackle increasing design complexity with shrinking timelines.Joining me today are two thought leaders who are at the forefront of this transformation:First, we welcome back Stephen Chavez, a senior printed circuit engineer with more than 30 years of experience. Stephen serves as a Senior Product Marketing Manager at Siemens EDA, where he helps drive AI adoption in PCB design workflows. He’s also the Chairman of the Printed Circuit Engineering Association (PCEA) and a PCEA and IPC Certified Master Instructor Trainer. Stephen recently authored the article “AI in PCB Design: It’s Already Here”, which forms the foundation of today’s discussion.Also joining us is Dave Wiens, Product Marketing Manager for the Xpedition Enterprise portfolio at Siemens EDA. With decades of experience in electronic design automation, Dave is a recognized expert in digital transformation and design innovation. He brings deep insight into how AI-driven tools are streamlining everything from system-level design to manufacturability, while empowering engineers to focus on innovation rather than repetition.We’ll unpack the practical applications of AI in PCB workflows—covering predictive design, simulation acceleration, and how these advancements are improving both reliability and time-to-market.If you're wondering what AI really means for the future of design—and what it doesn’t—you’ll want listen to this episode!

As the electric vehicle market accelerates, the reliability of the charging infrastructure becomes increasingly vital. Chargers that are down or malfunctioning can hinder adoption and erode consumer confidence. But who ensures these chargers stay up and running?Today, we're diving into that very topic with a trailblazer in the EV service space. My guest is Kameale Terry, co-founder and CEO of ChargerHelp!, a company revolutionizing how we think about EV charger maintenance and reliability. Under her leadership, ChargerHelp! has pioneered Reliability as a Service, developed a highly trained and diverse technician workforce, and shaped industry policies aimed at improving charger uptime.Kameale’s journey is as inspiring as it is innovative, leading a national movement for a more reliable and equitable EV charging network. With backgrounds in workforce development, clean tech, and digital operations, she’s uniquely positioned to tackle the challenges facing this growing industry.In this episode, we’ll explore the common causes of EV charger failures, the role data plays in predictive maintenance, the impact of new regulations like the National Electric Vehicle Infrastructure (NEVI) standards, and how ChargerHelp! is creating pathways into the clean energy economy for workers from all walks of life.If you've ever wondered how reliability translates to the EV world, or how technology and workforce innovation go hand in hand, you won’t want to miss this conversation.Kameale’s Company:ChargerHelp!https://www.chargerhelp.com

Today we're diving into a topic that keeps many executives awake at night—ERP implementations. More specifically, why so many of them fail and, perhaps more importantly, how to fix them midstream before they derail your operations.Joining me today is someone who knows this space inside and out—Chintan Sutaria. Chintan grew up working in an EMS business from a young age, gaining firsthand experience in the unique challenges of our industry. His career path took him into the world of business process consulting at some of the largest Big 5 firms, and he has since worked with numerous EMS companies on a wide range of projects.Many of you may recognize Chintan as the founder and former CEO of CalcuQuote, a well-known supply chain management software solution for the EMS industry. Recently, he founded, OpenJar, a consultancy dedicated to helping electronics manufacturers navigate complex business challenges—including ERP implementations.We’ll discuss his new company as well as his recent blog post, "Why Your ERP Implementation Failed (and How to Fix It Midstream)", explore common pitfalls, and uncover strategies to steer your ERP project back on course.Chintan's CompanyOpenJarhttps://openjartech.com

Today we're turning our attention to a cornerstone of modern electronics manufacturing: pick and place technology.Joining me is Tim Kang, CEO of Hanwha Semitech Americas. With nearly two decades of experience in the electronics manufacturing space—starting as a mechanical engineer and now leading one of the top pick and place equipment providers—Tim brings a wealth of insight into what it takes to build reliable assemblies.In this episode, we’re covering best practices for selecting the most appropriate pick and place machine, how to get the most out of your equipment, and the common mistakes that can compromise productivity and long-term reliability.Whether you’re a process engineer, a line operator, or anyone involved in electronics manufacturing, this conversation is packed with practical advice you can use right away.Hanwha's Website:https://www.hanwha-pm.com/en/product/smt/index.asp

Today we're exploring a concept that has deep roots in process safety and infrastructure management, but also has meaningful applications in electronics manufacturing: Damage Mechanism Reviews, or DMRs.My guest today is Dheeraj Narang, a corrosion and reliability engineering specialist, process safety activist, and digital innovation researcher with an impressive track record across the energy sector.Dheeraj has spent his career developing and implementing asset integrity programs for more than nine global energy companies across the U.S., India, and the Middle East.He’s also a visionary advocate for using advanced technologies, industry best practices, and safety standards to uplift regions and workers where such systems are still under development. Whether it's through his service on global conference committees or his contributions to cutting-edge digital initiatives, Dheeraj is on a mission to blend technology, safety, and human rights into a unified vision of operational excellence.In this episode, we’ll discuss:What Damage Mechanism Reviews are and why they matter.How DMRs tie into reliability programs like FMECA.How DMR thinking could benefit industries outside of oil and gas—including electronics manufacturingand how emerging technologies like AI and machine learning can amplify the impact of these reviews.Whether you're in energy, electronics, or any industry where reliability and safety are paramount, this is a conversation you won’t want to miss.Dheeraj's Contact Info:dnarang1@my.harrisburgu.eduReferences:Narang, D. Dual Benefits of Damage Mechanism Reviews. 2024 AiCHE Spring Meeting and 20th Global Congress on Process Safety, New Orleans, LA, March 25-27, 2024.Narang, D. Application of FMECA Methodology in Reliability Assessment of Complex Assets in Process Plant Industries. Reliability, Maintenance & Managing Risk Conference (RMMR) by American Society of Quality (ASQ), Pittsburgh-PA, July 25-26, 2024.Narang, D. Feature Selection Methodology for Developing a Supervised Machine Learning Model for Risk Based Inspection Study on Process Plant Assets. 79th Instrumentation and Automation Symposium, Mary Kay O’Connor Safety & Risk Conference, College Station-TX, October 22-24, 2024.Narang, D. Application of Machine Learning Concepts in Inspection Data Management System at Process Plant Facilities. 27th Process Safety International Symposium, Mary Kay O’Connor Safety & Risk Conference, College Station-TX, October 22-24, 2024.

On this episode of the Reliability Matters podcast, I left my usual studio for the IPC APEX Expo in Anaheim California.I interviewed two subject matter experts on topics related to electronic assembly.My guests are:Gerald Gardner, Global Product Manager at Weller, a manufacturer of hand soldering equipment fume extraction systems, and precision tools.Mike Young – CEO OF SASinno Americas, a manufacturer of wave and selective soldering equipment.More information on my guest's companies is available here:SASinno Americashttps://www.sasinnoamericas.comWellerhttps://www.weller-tools.com/us/en

On this episode of the Reliability Matters podcast, I left my usual studio for the IPC APEX Expo in Anaheim California.I interviewed three subject matter experts on various topics related to electronic assembly. My guests are:Greg Beck, Director of Sales at Absolute EMS, a contract manufacturer.Brian Watson, Co-Founder OF HyRel Technologies, a global provider of quick turn semiconductor modification solutions.Keith Sweatman, Technical Advisor at Nihon Superior, a manufacturer of soldering materials.More information on my guest's company is available here:Absolute EMShttps://www.absolute-ems.comHyRel Technologieshttps://hyrel.techNihon Superiorhttps://en.nihonsuperior.co.jp

Today, we’re diving deep into the world of electronics manufacturing from a unique vantage point—that of the press. My guest today is someone who has spent decades at the forefront of reporting on the electronics manufacturing industry. Mike Buetow, editor-in-chief of Circuits Assembly magazine, has covered everything from the latest technological advancements to the biggest challenges facing manufacturers today. If there’s a major trend shaping the industry, you can bet Mike has written about it, analyzed it, and spoken with the experts behind it. Mike is also the host of his own podcast, PCB chat, available at pcbchat.com. I am so proud to say Mike also syndicates this show at pcbchat.com.In this episode, we’ll explore the evolving landscape of electronics manufacturing, from supply chain disruptions and AI-driven automation to the future of ultra-high-density interconnects and the real impact of reshoring efforts. We’ll also get an inside look at what it takes to cover this ever-changing industry—how stories are chosen, what topics are making waves, and what challenges lie ahead. Printed Circuit Engineering Association (PCEA)https://pcea.netCircuits Assembly Magazine:https://circuitsassembly.com/ca/

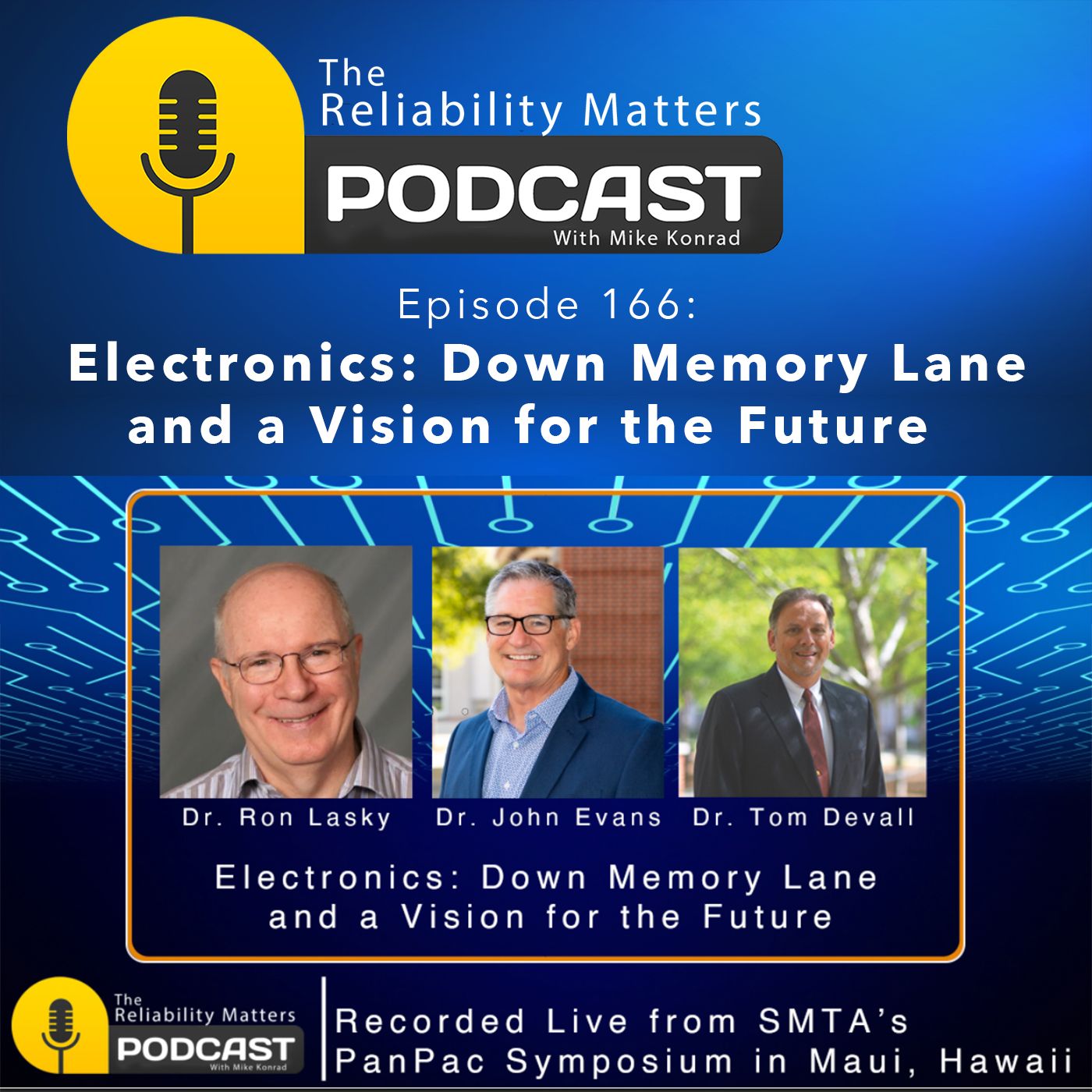

This episode is a little different in two ways. First, I didn’t record it in my studio. I recorded it at the SMTA Pan Pacific strategic Electronics symposium, affectionately known as PanPac, in beautiful Maui Hawaii.Each year, I record a Reliability Matters podcast at PanPac. Normally, the format of the show is I ask questions, and my guests provide answers. On this episode however, I decided to let my guest do all of the talking. The theme of this episode is Electronics: Down Memory Lane and a Vision for the Future. My three guests on this episode will share their view of the history of electronics from three different perspectives. My guests are Dr. Ron Lasky from Dartmouth College, Dr John Evans, and Dr. Tom Duval, both from Auburn University. They’ll share their perspectives on the history of the electronics industry in presentation format.

Today, we’re putting the spotlight on a critical component in surface mount technology, the stencil. These precision-engineered tools are the unsung heroes of electronic assembly, playing a pivotal role in ensuring accurate solder paste deposition and, ultimately, the reliability of your circuit assemblies.It's been long said that reliability begins at the solder print, and the print begins with the stencil.Joining us today is Elias Malfavon Jr, President of Metal Etch Services, Inc. a stencil manufacturer operating in San Marcos California. Metal edge services was founded 20 years ago in 2005. We’ll explore the fascinating journey of stencil production, from design and material selection to the advanced laser cutting technologies that ensure microscopic precision. We’ll also discuss the latest innovations in stencil technology, their impact on modern assembly processes, and how the industry is evolving to meet the challenges of ultra-high-density interconnects and miniaturization.So, sit back, relax, and let’s uncover the critical role of SMT stencils in today’s electronics manufacturing landscape.Elias Malfavon Jr's Contact Info:eliasjr@metaletchservices.comMetal Etch Services, Inc.https://metaletchservices.comThe D-Code Podcasthttps://www.youtube.com/@The-D-Code

Today, we're tackling a topic that has become increasingly vital in recent years: supply chain management. With global supply chains recently under immense pressure from disruptions, shortages, and growing complexity, the need for smarter, more efficient solutions has never been greater. And what better way to explore this than by discussing the cutting-edge role of AI-powered supply chain management software.My guest today is Sebastian Schaal, the founder and CEO of Luminovo, a company at the forefront of transforming how supply chains are managed in the electronics industry. Sebastian Schaal is the founder of Luminovo, a leading software provider revolutionizing the electronics supply chain. He holds two masters degrees—one in Electrical and Computer Engineering from the Technical University of Munich and another from Stanford University, where he was a Fulbright scholar focusing on Management and Computer Science. Before founding Luminovo, Sebastian gained diverse industry experience, working on AI algorithms for signal processing and computer vision at Intel and robotics companies NavVis and Magazino. Additionally, he served as a consultant at McKinsey, advising on data strategy.Sebastian and his team are leveraging artificial intelligence to streamline processes, enhance collaboration, and future-proof supply chain operations. In this episode, we'll explore how AI is reshaping supply chain management, the unique challenges facing the electronics industry, and what companies can do to stay ahead in an ever-changing global landscape. This conversation is packed with insights you won't want to miss. So, sit back, relax, and get ready to learn about the innovations that are revolutionizing supply chains worldwide. Luminovohttps://luminovo.comChapters:00:00:00 The Role of AI in Revolutionizing Supply Chain Management00:02:30 Innovation in Supply Chain Management: Origins and Vision00:04:56 The Unsung Heroes of the Electronics Supply Chain 00:07:25 The Impact of Supply Chain Challenges on Business Growth00:10:06 Challenges in Electronics Supply Chain Management00:12:28 Navigating the Complexities of Supply Chain Management 00:14:51 AI and Machine Learning in Modern Supply Chain Management 00:17:31 Enhancing Supply Chain Resilience with Digitalization and Collaboration00:20:03 Enhancing Collaboration with Digital Tools00:22:26 Automating Processes for Efficiency and Cost Optimization00:24:55 Choosing the Right Supply Chain Software: Industry-Agnostic Vs. Specific Vendors00:27:24 Advantages of Vertical Solutions in the Electronics Industry00:30:06 Challenges in Semiconductor Manufacturing and Supply Chain 00:32:35 Evolution of AI: From Engines to Intelligent Agents00:34:57 Transforming Manufacturing with Cloud and AI00:37:26 Overcoming Resistance to Digital Transformation in Supply Chains00:40:03 Overcoming Fragmented Data in Supply Chains00:42:36 Implementing New Systems and Avoiding Pitfalls00:45:08 Key Questions for Supplier Data Integration00:47:32 Common Mistakes in Selecting Supply Chain Management Systems00:50:04 Enhancing Supply Chain Integration and Automation00:52:23 Building a Global Supply Chain Network 00:57:19 Conclusion and Upcoming Podcast Schedule

Today we’re diving into a critical yet sometimes overlooked component that powers so many of the devices we rely on: batteries. Batteries are the heartbeat of countless electronic products, from medical devices and electric vehicles to consumer gadgets and industrial systems. Choosing the right battery is not a one-size-fits-all decision. It requires a keen understanding of the application, performance needs, and environmental demands. The right selection can make the difference between a product that excels in reliability and one that, quite literally, fails to deliver. But there’s more to batteries than just selecting the right chemistry or capacity. Safety is paramount. Poor battery selection, design, or management can lead to performance issues, overheating, or catastrophic failures. As we’ve all seen in headlines, battery malfunctions can result in recalls, damage to brand reputation, or, worse, safety hazards for users. To shed light on this vital topic, we’re joined by an expert in the field of battery technology. Alex Norman is a Battery Management System Designer at Pro Technologies, a well-established and trusted custom battery pack manufacturer, providing engineering capabilities from concept through production. Their leading edge manufacturing facility and headquarters is based in Pilot Mountain, North Carolina. Alex has deep experience in Printed Circuit Board Design, Product Development, Battery Management Systems and more. Alex is also a content creator, focusing mostly on electronics, battery, and BMS content available on his LinkedIn page and YouTube channel.Today, we’re going to explore how to choose the right battery for your assembly, best practices for integration, and how to mitigate potential safety risks. So, if you care about keeping your products powered, reliable, and safe, don’t bolt just yet – this podcast on batteries is positively charged with insights! Stick around and top off your battery knowledge!Alex's Contact Info:Alex Normananorman@eetengineer.comProTechnologies, Inc.http://protechnologies.comAlex's YouTube Channel:https://www.youtube.com/@eetengineerChapters:00:00:00 Choosing the Right Battery for Electronic Assemblies00:02:44 Exploring Battery Technology and Safety Concerns00:05:21 Starting a YouTube Channel: Journey and Growth00:07:55 Performance and Safety: Alkaline vs. Lithium-Based Batteries00:10:28 The Future of Sodium-Ion Batteries vs. Lithium-Ion00:13:12 Causes of Samsung Phone Battery Fires00:16:01 Advancements in Solid State Battery Technology00:18:44 Dangers of Swollen Lithium Batteries and Battery Safety00:21:19 Battery Charging Myths and Optimization Techniques00:24:04 Importance of Battery Management Systems (BMS)00:26:51 Primary vs. Secondary Batteries Explained00:29:28 Comparing Performance: Alkaline vs Rechargeable Batteries00:32:11 Impact of Temperature on Battery Performance00:34:51 Optimizing Battery Performance in Extreme Cold00:37:28 Lead Acid vs. Lithium Iron Phosphate: Battery Safety and Advancements00:39:56 Optimizing Battery Performance in Electric Cars00:42:36 Advanced Lithium Iron Phosphate Cells 00:45:24 Battery Regulations Impact and Safety Standards00:48:05 Battery Safety and Standards in Consumer Electronics00:50:49 Quality and Safety in Consumer Vs. Industrial Battery Cells00:53:25 The Importance of Proper Battery Recycling00:56:05 Lithium Iron Phosphate vs. Nickel Metal Hydride Batteries00:59:51 Humor and Technology: Creating Engaging Content01:01:10 Get Involved with Reliability Matters Podcast

On this episode, we’ll dive into the world of electronics testing with an expert within the electronics testing industry, Robert Boguski, President and Owner of Datest. Robert brings 44 years of experience in the design, fabrication, assembly, and testing of printed circuit boards (PCBs) and electronic systems. Under his leadership, Datest has become a premier provider of advanced, integrated PCBA testing and inspection services, serving both contract manufacturers and original equipment manufacturers since its founding in 1984. Robert's extensive background includes active participation in industry associations such as APICS, SMTA, and IPC, reflecting his commitment to advancing the field. He is also a columnist for Circuits Assembly Magazine, where he shares his insights on industry trends and challenges. In this episode, we'll explore Robert's journey in the electronics manufacturing industry, the evolution of testing technologies, and his perspectives on the future of electronics testing. Join us as we gain valuable insights from a leader whose career has been dedicated to excellence in electronic testing and manufacturing.Robert's Info:Robert Boguskirboguski@datest.comDatesthttp://www.datest.com

Today, we’re exploring a transformative topic: AI-based inspection technologies. Artificial intelligence is revolutionizing how we detect, analyze, and address defects in the electronics assembly process, combining precision with unparalleled speed to unlock new possibilities for efficiency and reliability.Our guest today is a leading innovator in this field. Priyansha Bagaria is the founder and CEO of Loopr AI, a company at the forefront of AI-powered solutions for manufacturing inspection. Priyansha holds an MBA in International business and Global management, a bachelors of engineering degree in computer Science, and she held a fellowship in data science at Cornell University.Her academic background, coupled with her entrepreneurial spirit, has positioned her as a trailblazer in applying AI to manufacturing processes.In this episode, we’ll explore the advancements Loopr AI is spearheading, how AI inspection technologies are reshaping traditional methods, and the tangible benefits AI offers to manufacturers striving for excellence. Loopr AI Website:https://www.loopr.ai

Today, we’re diving into one of the most transformative innovations of our time: electric vehicles and the vast infrastructure needed to support their growth. Joining us is Brian O’Leary, Global Head of of e-Mobility & Infrastructure at Indium Corporation, a leading expert with deep insights into the electronic assembly industry and its critical role in the EV revolution.As electric vehicles continue to redefine the future of transportation, the reliability and scalability of the infrastructure that powers them—particularly public EV charging stations—have become pivotal challenges. The electronic assembly industry is at the heart of these systems, from the semiconductors enabling fast charging to the sensors ensuring safe and efficient operation. However, with nearly 26% of public EV charging stations estimated to be non-functional at any given time, reliability remains a significant hurdle.This episode will explore the major reliability issues plaguing public EV charging stations, including power instability, component failures, and environmental challenges.How innovations in electronics design and assembly can address these challenges, from improving thermal management to leveraging advanced materials like those developed by soldering materials manufacturers.The exciting opportunities for the electronics industry to lead the charge in building a more resilient, reliable, and efficient EV infrastructure.Brian O’Leary brings a wealth of knowledge on how advanced materials, smart assembly techniques, and innovative designs can solve these pressing issues and accelerate the adoption of electric vehicles. Together, we’ll review the technical challenges, explore solutions, and look ahead to the bright future of electric mobility.Brian O’Leary's Contact Info:boleary@indium.comhttps://www.indium.com

Today we’re celebrating the end of another incredible year. This isn’t just any episode—it’s a time to reflect on the journey we’ve been on together, highlight some milestones, and share a heartfelt thank you to everyone who has made this podcast such a success. Can you believe it? Reliability Matters has now released 159 episodes! It feels like just yesterday we started this podcast with the mission to explore how industry experts and their knowledge contribute to the reliability of electronics. And here we are—growing, learning, and making a real impact in our field.But here’s what blows me away the most: over 85,000 downloads. That’s not just a number—it’s a testament to you, our amazing audience. Whether you’re listening in your car or on your morning jog, or watching this on our YouTube channel, you’ve made this podcast part of your journey. And for that, I’m deeply grateful.This year alone, we’ve covered some fascinating topics. From ultra-high-density interconnects to post-reflow inspection, from thermal profiling to cutting-edge coating materials—we’ve explored it all. Along the way, I’ve had the privilege of sitting down with some of the brightest minds in the electronics industry. Each guest has brought their unique insights, helping us all better understand the intricate science and art behind building reliable electronics.To my incredible guests—thank you. Your willingness to share your expertise, stories, and even a few laughs has been the lifeblood of this podcast. Every episode is a reflection of your generosity and brilliance.I also want to give a shout-out to you—yes, you. Whether you’re a long-time listener or you just discovered us this year, you’re the reason I do this. The messages, the comments, the emails—it’s all so inspiring. When you tell me how a particular episode helped solve a problem, spark a new idea, or simply make your day better, it reminds me why Reliability Matters matters.As we wrap up the year, I’m reminded of something I say often on this show: reliability isn’t just a goal; it’s a journey. It’s a series of choices, processes, and innovations that, together, ensure the technology we rely on lives up to its promise. And this podcast? It’s a part of that journey. It’s a space where we can learn together, challenge assumptions, and stay ahead of the curve in an ever-evolving industry.Mike Konrad's Contact Info:mike@mikekonrad.comhttps://www.reliabilitymatterspodcast.com