Discover Composites Weekly

Composites Weekly

300 Episodes

Reverse

On this episode, Nancy Hairston, CEO of MedCAD joins the show to discuss their innovative approach to the design and production of patient-matched medical devices using 3D printing. They've recently produced 3D-printed implants for wounded Ukrainian soldiers, an application where speed and accuracy can be life-changing. Their approach is 100% patient-customized, with every implant and every procedure planned and manufactured in-house in cooperation with a patient's attending surgical team. You can learn more about their company at https://www.medcad.com.

On this episode, Marty Johnson, VP of Product and Technical Fellow at 3D Systems, joins the show to take a clear-eyed look at additive manufacturing materials—what they can do, what they can't, and what engineers should realistically expect when composites and filled materials enter the 3D-printing conversation. Marty brings a mechanical engineering first perspective to additive manufacturing—cutting through marketing claims to focus on real data, long-term performance, and where printed composite materials truly make sense in aerospace, automotive, tooling, and beyond. As a company, 3D Systems delivers industry-leading 3D printing technologies, materials and software to high-value markets such as medical and dental, aerospace, space & defense, transportation & motorsports, AI infrastructure, and durable goods. You can learn more about them by visiting https://www.3dsystems.com.

On this episode, we're joined by Kjirstin Breure, President and CEO of HydroGraph—a company that may finally be turning graphene from a promise into a product. For more than a decade, graphene has been called a wonder material, but most producers struggled with impurities, inconsistency, and the inability to scale. HydroGraph has taken a different path—developing a proprietary explosion-synthesis process that delivers pure, identical batches of fractal graphene at industrial scale. In just the past year, HydroGraph has moved from lab-driven R&D to real commercial momentum, with dozens of active customer projects across composites, aerospace, medical devices, coatings, and energy storage. With aggressive U.S. expansion underway, growing engagement with federal and defense agencies, and discussions around deeper capital market integration, the company is hitting a rare inflection point. You can learn more by visiting their website at https://hydrograph.com.

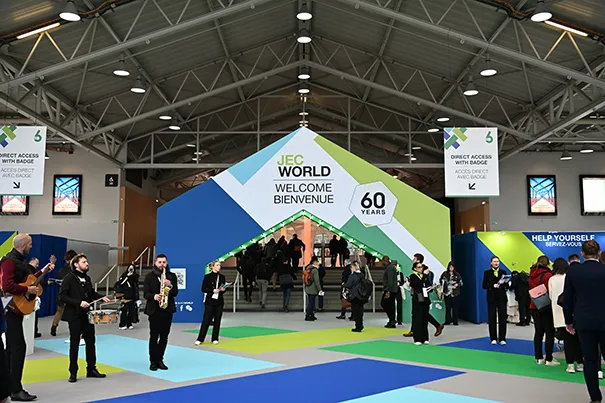

On this episode Thomas Lepretre joins the show to talk about JEC World 2026. Thomas is Vice President of Events, Sales & Operations at JEC Group. We'll be discussing what's in store for this year's big show in Paris, March 10-12. JEC World's mission is to promote composite materials globally by connecting innovation, business, and applications across all major industries. You can learn more about this year's event by visiting https://www.jec-world.events.

On this episode, Daniel Murphy, founder of Alcove Media, joins the podcast. His company helps companies turn trade shows from expensive branding exercises into measurable revenue engines. Daniel works closely with technology companies that invest heavily in expos but struggle to connect booth traffic to real sales outcomes. In this conversation, we break down why most trade shows fail to deliver ROI, how a lack of strategy quietly bleeds marketing budgets, and what it takes to generate qualified leads, engagement, and follow-through that converts. If your company spends serious money on trade shows, and expects more than vague "exposure," this episode is one you'll want to take notes on. You can learn more by visiting https://tradeshowsecrets.com.

On this episode, Dr. Michael Murdoch joins the podcast to discuss how visual cues can act as diagnostics for material performance, and how engineers can preview color, gloss, translucency, surface texture, and material mixtures long before a physical prototype exists. He is the head of the Integrated Sciences Academy at the Munsell Color Science Lab at Rochester Institute of Technology. His work focuses on how material appearance—things like color, gloss, translucency, and surface texture—can be digitally simulated, measured, and used as meaningful data long before a physical part ever exists. With an early career as a chemical engineer at Eastman Kodak, working hands-on with thermoplastics and injection-molded components, Dr. Murdoch brings a rare blend of manufacturing experience and advanced research insight. The Munsell Color Science Laboratory and the Program of Color Science unite to form one of the world's foremost color science research and education organizations. Their mission is to provide world-class education, research, and outreach in all areas of color science. You can learn more at https://www.rit.edu/science/munsell-color-lab.

On this episode, Ryan Condron joins the podcast to discuss his vision for moving cargo containers across vast distances with zero emissions. Ryan is the CEO of Float, a company working to build the next generation of aerial freight systems—fusing hydrogen-powered carbon fiber blimps with quadcopter agility to move cargo containers across vast distances with zero emissions. You can learn more at https://floatair.com.

On this episode, Dr Robert Brüll, founder and CEO of FibreCoat joins the show to discuss their strategic partnership with Lofith Composites to develop next-generation thermoplastic composites for space. This partnership joins FibreCoat's expertise in fibre coatings with Lofith's thermoplastic tape and composite manufacturing. Together, the companies will integrate FibreCoat's coated fibres into Lofith's recyclable, high-performance composites to produce lightweight structural materials designed to meet the extreme demands of space. The first orbital demonstration of the joint material is planned for 2026, when a satellite will carry test panels into orbit for 12 months.

On this episode, Michael Campbell, president of ACD Consulting, a division of Coltala Aerospace, joins the podcast. Michael works closely with aerospace and defense programs across the U.S., helping organizations navigate workforce constraints through smarter engineering deployment, embedded expertise, partnerships, and technology adoption. You can learn more by visiting https://www.acdc.aer.

On this episode, Roy Silvas, Business Development Director at Enduro Composites joins the podcast. We'll discuss where composites fit in the rapidly expanding data-center ecosystem, what adoption barriers still exist, and how the next generation of facilities could benefit from smarter material choices. You can also read Roy's recent article at https://www.cablinginstall.com/data-center/article/55313169/integrating-composites-into-data-center-design.

On this episode, Dr. Valentyn S. Volkov joins the show to discuss how AI is being used to generate new materials. Dr. Volkov is ranked among the top 2% of scientists worldwide, with over 260 publications and more than 8,000 citations. He is also the founder of XPANCEO, a Dubai-based deep tech company developing the world's first invisible and weightless smart contact lenses, merging all your gadgets into one infinite screen.

On this episode, we'll delve into the world of printable biomaterials designed to heal the human body more quickly and safely. Our guest is Robert Joyce, founder of FibreTuff, a company developing a new class of bio-based composites—including a unique PAPC + Nylon 66 "alloy" that could redefine how we approach bone repair and tissue integration. FibreTuff's material isn't just strong and printable—it's amphiphilic, meaning it promotes natural cell adhesion and faster healing. You can learn more at https://fibretuff.us.

On this episode, Rob Glenn of Forza joins the show. In business since 1979, Forza is a family-owned adhesive, sealant & specialty tape manufacturer based in the US. They supply the global industry with superior, high-performing, customized products. You can learn more by visiting https://forzabuilt.com.

On this episode, Brittany Greer, executive director of Rosie Riveters, joins the podcast.Their organization works very closely with the manufacturing industry with a particular focus on preparing the workforce of tomorrow. They work to close the gaps in today's workforce by increasing participation in STEM, fostering critical thinking and problem solving skills. Brittany is a guest writer for The AI Journal and we'll be discussing their work in preparing the the gneration of workers with the skills needed to succeed alongside AI.

On this episode, Joe Steele of LIFT joins the podcast to share some recent news. Their organization has been awarded a contract to accelerate the development of ceramic-based materials for use in industrial and defense applications. This new four-year, $9 million "Critical Materials Processing" program will advance the state of technology and readiness for ceramics, ceramic matrix composites (CMCs), and ultrahigh-temperature materials. LIFT is an accelerator connecting advanced materials, manufacturing processes, systems engineering and talent development enhancing America's manufacturing competitiveness, national economy, and security.

On this episode, Cindy Squires joins me to highlight Composites Evolution taking place October 22-23 in Knoxville, TN. This event brings together leading manufacturers, suppliers, and technical experts to explore practical, profitable solutions to the EPA's new styrene regulations. This focused, forward-looking conference will show you how to turn compliance into a competitive advantage – boosting efficiency, improving processes, and unlocking new market opportunities. You can learn more by visiting https://acmanet.org/event/composites-evolution.

On this episode, we'll be featuring several interviews from day two at CAMX 2025, including: Max Thouin of Fairmat discussing FairPly Recycled Technology. 0:21 Mike Siwajek, VP of R&D at CSP discussing their ultra-lightweight TCA Float™: 5:47 Yannick Willemin, founder of Catalysium: 10:39 Imad Atallah, VP of Product Management at Hexcel Corporation: 19:31 David Leach, SAMPE Fellow & Co-chair of the CAMX Conference: 35:34 Jacob Clark of ReForm Composites Engineering: 43:38

On this episode, we'll be featuring several interviews from CAMX 2025, including: John Kehoe of Boaz Partners: 2:24 Paul Salach discussing SUSTAINA® Loop by Owens Corning: 12:04 Gary Owen, CEO of Lineat Composites Limited: 18:54 Russell Gentry, Professor of Architecture and Civil Engineering at GA Tech discussing the Monogirder BladeBridge: 23:39 Matthew Hardman discussing Loop Technology's FibreLINE system: 30:45 Mark Adams of Polynt Group and Dr. Wayne Huberty from Mississippi State University discussing accelerated composite manufacturing using CRTM and 3D-printed thermoset tooling: 38:45 Bryan Beimel of Pulflex Technologies: 51:52 Dr. Moutushi Dey discussing AI in Manufacturing: 58:46 Monica Rommel of Specialty Materials and Chantel Camardese of Toray Advanced Composites discussing the Hy-Bor® technology: 1:07

On this episode, Cindy Squires and Rebekah Stacha join me to talk about CAMX 2025, taking place in just over a week down in sunny Orlando, FL (Sep. 8-11). You can still register by visiting https://www.thecamx.org.

On this episode, Jamey Embree and Ken Bisconer from L&L Products join us to discuss their work in bringing L&L's extensive expertise to solutions for the aerospace, construction, sporting goods, and emerging mobility industries. L&L is well-known in the automotive space for developing innovative solutions that help OEMs create lighter, stronger, and quieter vehicles, but they also provide high-performance solutions for Aircraft interiors, electric Vertical Take-Off and Landing vehicles (eVTOL), and Unmanned Aerial Vehicles (UAV), including drones. On this episode, we'll be discussing three products L&L will be highlighting at CAMX in Orlando next month. They will be located at booth Q45 on the exhibit hall at CAMX. These new products include: PHASTER® : A proprietary two-component ambient temperature curing technology with superior adhesion performance and processing ease, in various indoor or outdoor application conditions. https://phaster.llproducts.com/ Continuous Composite Systems ™ (CCS™): Continuous fiber-reinforced composite materials that can be used as a carrier when combined with our highly engineered sealants and/or structural adhesives. The system is designed to provide strength, stiffness, and rigidity to a lightweight structure. https://ccs.llproducts.com/ InsituCore®: a family of one-component, heat-activated foaming materials that can be used to create composites with a foam core. Placed in a heated tool, the material foams to fill the mold cavity and form net-shape parts without time-consuming machining processes or energy-intensive autoclave operations. https://insitucore.llproducts.com/