Discover CDFAM Computational Design Symposium

CDFAM Computational Design Symposium

CDFAM Computational Design Symposium

Author: Duann Scott

Subscribed: 2Played: 222Subscribe

Share

© Bits to Atoms

Description

137 Episodes

Reverse

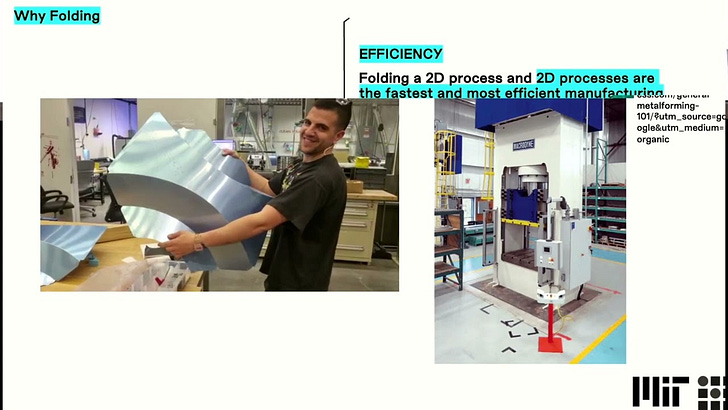

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:MITPresenter:Alfonso Parra RubioCrease, Fold, Transform. Presentation AbstractFolding is a fundamental process found throughout nature on multiple scales. Rather than altering the material itself, folding transforms its shape, offering a powerful means of engineering without compromising integrity.This presentation explores, from an engineering and design perspective, the unique potential of folding and discrete assembly as a design and manufacturing tool across multiple scales in engineering.From millimeter-scale bulk cellular materials to meter-scale structural corrugations and actuated robotic systems, and ultimately to architectural shell structures spanning tens of meters, folding enables the creation of high-performance, architected materials.Speaker BioAlfonso Parra Rubio is a PhD candidate at the Massachusetts Institute of Technology, working at the Center for Bits and Atoms led by Neil Gershenfeld. His research explores how folding and discrete assembly can be combined to design and manufacture architected materials across multiple scales: from bulk cellular materials (millimeters to centimeters), to structural corrugations and actuated systems (centimeters to meters), and up to architectural-scale shell structures (meters to decameters). His work fundamentally explores how materials and structures are designed, engineered, manufactured, and assembled. In addition to his academic research, he founded RnKolektive, a collaborative platform for sculptural exploration. This parallel practice focuses on mixed-media works that merge folding techniques with blown glass, creating pieces that use the same research contributions but with an expressive intention. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/OrganizationPrinceton UniversityPresenter:Tuo ZhaoSuper-Modular Chiral Origami MetamaterialsPresentation AbstractMetamaterials with multimodal deformation mechanisms resemble machines, especially when endowed with autonomous functionality. A representative architected assembly, with tunable chirality, converts linear motion into rotation (1). These chiral metamaterials with a machine-like dual modality have potential use in areas such as wave manipulation, optical activity related to circular polarization and chiral active fluids. However, the dual motions are essentially coupled and cannot be independently controlled. Moreover, they are restricted to small deformation, that is, strain ≤2%, which limits their applications. Here we establish modular chiral metamaterials (2), consisting of auxetic planar tessellations and origami-inspired columnar arrays, with decoupled actuation. Under single-degree-of-freedom actuation, the assembly twists between 0° and 90°, contracts in-plane up to 25% and shrinks out-of-plane more than 50%. Using experiments and simulations, we show that the deformation of the assembly involves in-plane twist and contraction dominated by the rotating-square tessellations and out-of-plane shrinkage dominated by the tubular Kresling origami arrays. Moreover, we demonstrate two distinct actuation conditions: twist with free translation and linear displacement with free rotation. Our metamaterial is built on a highly modular assembly, which enables reprogrammable instability, local chirality control, tunable loading capacity and scalability. Our concept provides routes towards multimodal, multistable and reprogrammable machines, with applications in robotic transformers, thermoregulation, mechanical memories in hysteresis loops, non-commutative state transition and plug-and-play functional assemblies for energy absorption and information encryption.References:(1) Frenzel, T., Kadic, M. & Wegener, M. Three-dimensional mechanical metamaterials with a twist. Science 358, 1072–1074 (2017).(2) Zhao, Tuo (presenter), Dang, X., Manos, K., Zang, S., Mandal, J., Chen, M., & Paulino, G. H. Modular chiral origami metamaterials. Nature, 640(8060), 931-940 (2025).Speaker BioTuo Zhao is a postdoctoral research associate at Princeton University. His expertise is in computational mechanics, nonlinear topology optimization, soft robotics, and mechanical metamaterials. Tuo is currently addressing the scalability challenge for developing useful metamaterials. By integrating an untethered actuation scheme (e.g., three-dimensional magnetic fields and micro-magnetic responsive materials), he designs micro-robotic machines with tunable properties on demand. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization: STILFOLDhttps://www.stilfold.com/Presenter:Julia HannuGreener by Every Fold. Strength in Every Curve. Presentation AbstractThis talk introduces STILFOLD’s innovative origami-inspired manufacturing process, where metal sheets are folded into form. The process uses both straight and curved crease folding, expanding the possibilities of how sheets can be transformed into products. This, to make curved crease folding accessible to a wider community of designers and engineers – moving it from a niche research technique into a scalable industrial method. Our aim is to develop a more environmentally friendly way of making things – reducing the number of parts, energy consumption, material use and transportation needs. Achieving this involves multiple layers of complexity: from designing folding patterns of efficient structures to developing dedicated folding systems for production at scale.The presentation will share insights into how STILFOLD is pushing to transform folding into a sustainable and practical approach to manufacturing – and what that could mean for the future of design, engineering, and production.Speaker BioJulia Hannu is a Software Engineer and Computational Design Lead at STILFOLD, where she develops digital tools and algorithms to enable new approaches to sustainable manufacturing and design. Her work centers on transforming complex geometric challenges into practical, efficient, and user-friendly solutions. With a background in architecture and an MSc in Architectural Computation from UCL, she combines experience from practice and academia to bridge technology, design, and sustainability. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

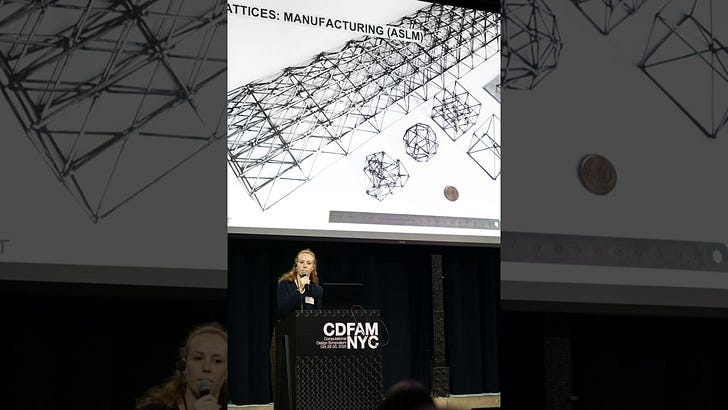

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/OrganizationTetmethttps://www.tetmet.net/Presenter:Rachel AzulayConformal Lattice Design Made Easy: A CAD-Integrated ApproachPresentation AbstractTETMET has developed an innovative process to produce large-scale lattice structures in an automated way, enabling applications across multiple industries.However, existing lattice design software has significant limitations, particularly when it comes to creating efficient, manufacturable conformal lattice structures. Most available tools were developed with general 3D printing in mind, offering only basic latticing capabilities that fail to meet the demands of more advanced applications.Our approach takes a different path by integrating lattice design seamlessly into traditional CAD workflows. By combining the flexibility of CAD with the specific requirements of lattice generation, we significantly enhance the design process—allowing engineers to work with familiar tools while unlocking new possibilities for complex, high-performance structures.Speaker BioRachel holds a PhD in Lattice Structure Design and leads the Application Engineering team at TETMET. She specializes in transforming complex customer challenges into innovative, lightweight lattice solutions, bridging cutting-edge research with real-world applications. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/OrganizationScawo3DPresenter:Philip Schneider + Timo ZollnerComputational Design for Assembly: Automating Design Workflows for 3D Concrete Printed Freeform StaircasesPresentation AbstractBuilding large freeform reinforced concrete staircases has always been a challenge. Traditional methods rely on labor-intensive wooden or EPS formwork, making many designs too expensive. This can be changed with Selective Paste Intrusion, a new 3D concrete printing technique by Scawo3D using a large particle bed, with no constraints related to print overhangs or angles.While fabrication now allows full geometric freedom, the design process became the bottleneck. Our previous AutoCAD-based solution, initially developed for producing G-codes for CNC-milling EPS formwork blocks, was not viable for 3D printing. Manual 3D modeling made scaling production impossible, leaving the printer underused. To solve this, Timo Harboe Zollner developed an automated workflow that cuts design time by up to 95%. This approach balances automation with intuitive user input, transforming 2D geometry into finely detailed 3D models in minutes. It integrates SubDs, meshes, volumetric modeling, and implicit modeling, achieving in moments what once took days.This presentation highlights the adaptation of computational design to a new production method—one with only few geometric constraints yet capable of achieving material properties comparable to standard concrete.Speaker BioPhilip Schneider Computational & Architectural Design Lead at Scawo3D and founder of Skeno. He holds a M.A. from TU Munich with a focus on computational methods in architecture and specialises in 3D concrete printing by Selective Paste Intrusion at an architectural scale. Since 2022, he has led the design and fabrication of the first projects realised by SPI in academia and industry.Timo Harboe Zollner is the founder of Timo Harboe ApS, a Copenhagen-based consultancy specializing in automating processes related to geometry, particularly within additive manufacturing. With a background in structural engineering and computational design, Timo collaborates with clients to develop parametric workflows and digital tools that streamline complex design and fabrication processes. His recent projects include automating the generation of 3D-printed formwork for freeform concrete staircases together with Scawo3DAbout CDFAM:CDFAM is a global symposium series at the forefront of computational design, advanced manufacturing, and performance-driven engineering. With a strong emphasis on innovation, CDFAM highlights how leading companies and researchers are leveraging AI, machine learning, and simulation technologies to drive the next generation of design tools, workflows, and digital fabrication methods.The symposium fosters cross-disciplinary collaboration and knowledge exchange between designers, engineers, and technologists exploring the cutting edge of digital design — from generative workflows.Past presenters and partners include companies such as NVIDIA, NASA, New Balance, BMW, ARUP, Foster +, Partners, BIG, Autodesk, Dassault Systèmes, nTopology, PyhicsX, Neural Concept, Siemens and more, showcasing how computation and AI are transforming everything from aerospace to footwear.Learn more at https://cdfam.com This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

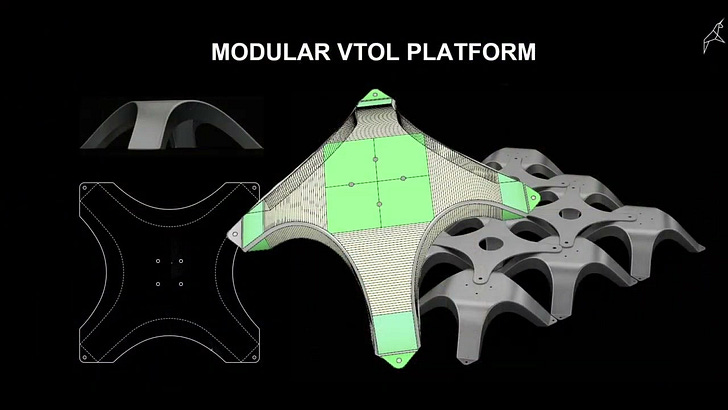

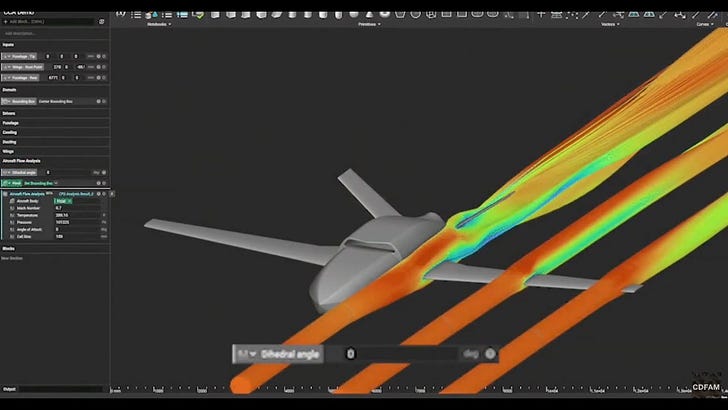

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/nTopBradley RothenbergFrom 3 Configurations to 300: Rapid Trades for Advanced Aircraft DesignPresentation AbstractAircraft development timelines have collapsed from 7 years to 18 months, but design tools still assume you have years to iterate. The result: teams freeze architecture in week 2, before they understand the design space, and spend the rest of the program managing the consequences.The core problem is going from requirements-to-design is just too slow. Serial design evaluations, manual CAD updates that fail to parametrize correctly, and expensive simulation cycles create weeks-long iteration loops.nTop solves this through three architectural principles: Parametric models that remain robust under any design change. No geometry failures, no manual repairs; integrated notebooks capturing engineering knowledge in executable form; and GPU-native solvers enabling interactive design-analysis cycles with performance feedback in minutes.What’s the alternative? Exploring 3-4 hand-crafted configurations slowly or quickly committing to a single concept. Neither is likely to win. nTop enables systematic exploration of hundreds of variants in the time that traditional approaches evaluate three.This presentation demonstrates real examples: Group 1-3 UAS configurations generated and flight-tested in weeks, hypersonic vehicle trade studies evaluating hundreds of variants, and rapid weapons platform sizing with integrated CFD.The result: teams explore more, fail fast, and learn faster—improving win rates through comprehensive trade studies and defensible performance predictions.About CDFAM:CDFAM is a global symposium series at the forefront of computational design, advanced manufacturing, and performance-driven engineering. With a strong emphasis on innovation, CDFAM highlights how leading companies and researchers are leveraging AI, machine learning, and simulation technologies to drive the next generation of design tools, workflows, and digital fabrication methods.The symposium fosters cross-disciplinary collaboration and knowledge exchange between designers, engineers, and technologists exploring the cutting edge of digital design — from generative workflows.Past presenters and partners include companies such as NVIDIA, NASA, New Balance, BMW, ARUP, Foster +, Partners, BIG, Autodesk, Dassault Systèmes, nTopology, PyhicsX, Neural Concept, Siemens and more, showcasing how computation and AI are transforming everything from aerospace to footwear.Learn more at https://cdfam.com This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:Pasteur LabsPresenter:Alexander LavinThe Unreasonable Effectiveness of Simulation IntelligencePresentation AbstractScientific rigor & engineering reliability have always been important yet contentious topics in the AI field. Recent AI trends crank up model sizes, but at what costs? Transparency and verifiability, amongst others that are core to industrial R&D—not to mention the massive spending. These costs are perhaps felt the most in physics simulation and digital engineering. Enter simulation intelligence (SI). SI is not antithetical to AI, rather it is the pragmatic approach to bringing AI capabilities into industrial R&D. Rather than LLMs atop legacy engineering tools or Foundation Models to opaquely replace physics solvers, we look to the combinatorial possibilities available when SI motifs are brought together—namely differentiable physics programming and surrogate modeling, yielding multiphysics modules. This talk will describe the distinction, that is: static CAE simulations vs dynamic simulators, bespoke surrogate models vs flexible multiphysics modules, massive black-box AI vs efficient programmatic SI. Examples from the SI Platform will elucidate end-to-end digital engineering pipelines, in diverse sectors from nuclear energy and data centers, to aerospace and automotive safety.Speaker BioAlexander Lavin is a leading expert in AI-for-science and probabilistic computing. He’s Founder & CEO of Pasteur Labs (and non-profit “sister” Institute for Simulation Intelligence), reshaping R&D with a new class of AI-native simulators, commercializing in energy security, aerospace, materials & manufacturing sectors (https://simulation.science). For the last dozen years, Lavin has focused on artificial general intelligence (AGI) research with top startups in neuroscience and robotics (Vicarious, Numenta), and sold his prior ML-simulation startup Latent Sciences to undisclosed pharmaco in neurodegeneration R&D. Lavin also serves as AI Advisor for NASA, overseeing physics-ML efforts for the NASA-ESA “Digital Twin Earth” projects. Previously, Lavin was a spacecraft engineer with NASA and Blue Origin, and won several international awards for work in rocket science and space robotics (including Google Lunar XPrize during graduate studies at Carnegie Mellon). Lavin was named Forbes 30 Under 30 in Science, and a Patrick J. McGovern Tech for Humanity ChangemakerAbout CDFAM:CDFAM is a global symposium series at the forefront of computational design, advanced manufacturing, and performance-driven engineering. With a strong emphasis on innovation, CDFAM highlights how leading companies and researchers are leveraging AI, machine learning, and simulation technologies to drive the next generation of design tools, workflows, and digital fabrication methods.The symposium fosters cross-disciplinary collaboration and knowledge exchange between designers, engineers, and technologists exploring the cutting edge of digital design — from generative workflows.Past presenters and partners include companies such as NVIDIA, NASA, New Balance, BMW, ARUP, Foster +, Partners, BIG, Autodesk, Dassault Systèmes, nTopology, PyhicsX, Neural Concept, Siemens and more, showcasing how computation and AI are transforming everything from aerospace to footwear.Learn more at https://cdfam.com. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:ARENA-AIPresenter:Pratap RanadeArtificial Intuition: Building an AI Mind for Electromagnetic DesignPresentation AbstractMost advances in computational design focus on mechanical structure — domains we can visualize and have evolved an intuition for. But as modern hardware becomes increasingly software defined, the unseen and unintuitive world of electromagnetism is taking center stage. Conventional solvers can simulate fields, yet they cannot imagine new ones. In this talk, I’ll share how we’re pushing past that frontier by creating artificial intuition — AI systems that learn physical behavior inductively, not deductively. Drawing inspiration from quantum experiments like the Kondo mirage, where discovery outpaced simulation, I’ll show how our team built Atlas: an AI that learns directly from electromagnetic test data to verify, optimize, and eventually postulate new designs. We’ll share results from realworld applications in semiconductors and aerospace, and offer a teaser of what’s to come over the next twelve months.Speaker BioPratap Ranade, CEO and Founder of ARENA-AIJoin us at CDFAM Barcelona April 8-9, 2026, the premier symposium for computational design, AI, and engineering innovation.Don’t miss your chance to connect with global leaders in design and technology.Register by February 1st to secure the early bird rate and be part of the conversation shaping the future of design, architecture, and advanced manufacturing. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:University of Southern CaliforniaPresenter:David GerberDigital Twining a Living LabPresentation AbstractThe Living Lab Project is an innovative Viterbi initiative designed to enhance academic research and provide practical learning experiences through real-time monitoring and analysis of the new Ginsburg Hall building. Leveraging sensors embedded in the building’s systems and integrating cutting-edge digital twin technology, this project captures and analyzes data on energy usage, water consumption, building health and occupant well being, and more, offering a comprehensive dataset for faculty and student research. The project treats our newest building, a LEED platinum accredited building, as a scientific instrument to support both near term and longitudinal research across a multitude of disciplines including but not limited to Human Building Interaction, to AI, and sustainability related research fieldsSpeaker BioDr. Gerber holds a joint appointment at USC’s Viterbi School of Engineering and the USC School of Architecture as a Professor of Civil and Environmental Engineering Practice and of Architecture. Dr. Gerber is the program Director for the Civil Engineering Building Science undergraduate program and the program Director for the Masters of Science in Emerging Technologies for Construction Program. Dr. Gerber is an associate director in the Office of Technology Innovation and Entrepreneurship. He teaches in the Viterbi School of Engineering, the School of Architecture and at the Viterbi Startup Garage. Dr. Gerber’s professional experience includes working in architectural, engineering and technology practices in the United States, Europe, India and Asia for Zaha Hadid Architects in London; for Gehry Technologies in Los Angeles; for Moshe Safdie Architects in Massachusetts; The Steinberg Group Architects in California; and for Arup as the Global Research Manager. Dr. Gerber’s research has been industry, fellowship, DoD, and NSF funded and is focussed on the development of innovative systems, tools, methods for design of the built environment. He has developed digital twin technologies and advises, and co advises PhD students from Architecture and Engineering on topics that integrate computer science, robotics, engineering, with architecture. David Gerber received his undergraduate architectural education at the University of California Berkeley (Bachelor of Arts in Architecture, 1996). He completed his first professional degree at the Design Research Laboratory of the Architectural Association in London (Master of Architecture, 2000), his post professional research degree (Master of Design Studies, 2003) and his Doctoral studies (Doctor of Design, June 2007) at the Harvard University Graduate School of Design. Dr. Gerber was the recipient of the Frederick Sheldon Fellowship at Harvard University and was a Research Fellow at MIT’s Media Lab in the Smart Cities group. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:CORE studio | Thornton TomasettiPresenter:Sergey PigachEngineering Intelligence: Practical Applications of AI in Structural Engineering PracticePresentation AbstractArtificial Intelligence is no longer a distant future. It is actively shaping how structural engineers work, collaborate, and innovate. This session offers a practical look into how Thornton Tomasetti’s CORE studio is advancing AI integration within the firm, with a focus on real-world tools and workflows that enhance engineering practice. Attendees will explore the firm’s hands-on experimentation with generative models, domain-specific co-pilots, and applications of agentic workflows, as well as strategies for cross-disciplinary collaboration that ensure AI tools align with engineering priorities. The presentation will also share lessons learned in promoting firmwide adoption, cultivating technical fluency, and building an inclusive innovation culture that empowers all team members to contribute to AI-driven transformation.Speaker BioSergey Pigach is a Senior Associate Applications Engineer at CORE studio | Thornton Tomasetti. Sergey’s work builds on his architectural training by bridging the domains of technology and design, driving him to develop computational tools for architects, designers, and engineers. Since joining CORE studio he has worked on desktop and web-based projects including Swarm, a cloud compute solution for Grasshopper; ShapeDiver, a desktop client integration following a merger; and—most recently—Cortex, CORE Studio’s new MLOps platform. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:NVIDIAPresenter:Ian PeglerKeynote Presentation: How NVIDIA Is Accelerating Product DevelopmentPresentation AbstractComputational simulation and design have transformed product development by significantly reducing time and costs. However, designing complex products remains a challenging and resource-intensive process.In this presentation, we will explore key industry challenges and demonstrate how NVIDIA is leveraging innovative solutions to address them. Specifically, we will highlight the use of accelerated computing to enable faster, higher-fidelity simulations, and AI surrogate models to provide designers with real-time feedback.Additionally, we will discuss integrated approaches that combine these technologies to create responsive, real-time digital twins. The foundational platform supporting these advancements will be examined, along with real-world industry applications illustrating their impact.Speaker BioIan Pegler is a member of the Computer-Aided Engineering (CAE) team at NVIDIA. With a career largely focused on computational fluid dynamics (CFD), Ian has extensive experience across various industries, including aerospace, automotive, energy, and marine. Currently, he collaborates with small and start-up CAE companies to help accelerate their engineering tools and workflows. Ian holds a Master’s degree in Aerospace Engineering from the University of Southampton, UK, and is based in Chicago.Join us at CDFAM Barcelona, April 8-9, 2026 to connect with leading designers, engineers and architects at the forefront of the adoption of AI and Machine learning through computational design for two days of knowledge sharing and networking. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/OrganizationDavid Burpee DesignPresenter:David BurpeeComputational Morphogenesis: Leveraging Proceduralism to Unlock Temporal DesignPresentation AbstractCurrent paradigms of design and engineering operate on the premise that realized designs are static – that is once they are designed and manufactured they exist in their final state. Likewise even flexible computational systems tend to not incorporate the dimension of time as a design tool. Despite dozens or hundreds of sliders, variables, and graphs, most products – even those designed computationally – are “frozen” at a certain point and designed as a static object.New advancements in material science research particularly around Engineered Living Materials or ELMs have elucidated these shortcomings in our design and engineering workflows. How can we model, simulated, validate, product performance or behavior in this dynamic, temporal environment? We need new processes, workflows, methods, and tools in order to effectively utilize this new dimension of material typologies, as well as continue to design in ways that are more connected to engineering simulation and validation.In this presentation I will explore the use of proceduralism as an essential creation environment that is uniquely able to design in conjunction with these temporal constructs. I will present a subset of my work that utilizes computationally-driven simulations for the creation of physical product, as well as some of my teaching and research through the NSF grant project designing with Engineered Living Materials at the University of Washington.Speaker BioDavid Burpee is a multidisciplinary Computational Design Leader based in the Pacific Northwest, with expertise spanning Footwear, Apparel, Consumer Goods, Automotive, Medical, and Architecture industries. He lectures on Computational Design and Algorithmic Thinking at the University of Washington and is a Computational Researcher on a National Science Foundation grant exploring Engineered Living Materials (ELMs).With over a decade of Computational Design experience, David has delivered advanced design strategy, tools, and training for companies including Nike, PUMA, FILA, General Motors, Harry’s Razors, and EQLZ. His work demonstrates a proven methodology that merges creativity, deep technical capabilities, and broad market impact.Originally trained as an Architectural Designer with a Master of Architecture from USC, David has contributed to highrise and supertall projects in Los Angeles, Seattle, and across Asia. His work integrates computational approaches at every scale, from skyscrapers to small installations.Driven by a passion for biomimicry, generative systems, and sustainable innovation, David applies computational design to address complex ecological and social challenges through creative, high-performance solutions.Join us at CDFAM Barcelona, where the forefront of computational design and advanced manufacturing comes alive. This gathering brings together innovators, researchers, and industry leaders to explore the future of design through simulation, generative tools, and performance-driven workflows. Set in one of Europe’s most dynamic creative hubs, CDFAM Barcelona is the place to connect, learn, and be inspired by what's next in the world of computational fabrication. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:New BalancePresenter:Samuel WhitworthComputational Craft: One Footwear Designer’s Quest To Replace HimselfPresentation AbstractFootwear design, like many design domains, has long been defined by the combination of two-dimensional drawings and designers’ intuition. While these remain important elements of the field, various digital design methods are currently surging and have significantly altered the traditional footwear design process. This presentation will explore the opportunities presented by this shift through the lens of my own experience as an industrial designer turned computational designer—specifically how the application of computational methods has allowed me to expand the types of design solutions I can explore. In this sense, it’s been a journey of “replacing” my traditional industrial design role with a new hybrid role defined by what I call “computational craft.”Computational craft can be defined as a collaborative human/computer design approach, where the computer extends the reach of the human designer, while the human grounds computational results in the real world of manufactured objects and human sensibility. I will demonstrate several examples of this method in Grasshopper, including Kangaroo-based simulations, multi-objective optimization, and mesh generation/manipulation. Audience members will be able to take away new inspiration for using computational methods in their design workflows, and a feeling of confidence that computational design is accessible to anyone regardless of academic or professional background.Speaker BioSamuel Whitworth is a Computational Designer II at New Balance Athletics, where he has contributed to both inline and innovation projects for the past six years (recent releases include the SuperComp Elite v4 and More v5.) Sam focuses on the intersection of footwear geometry and function using scripting, simulation and functional prototyping, leveraging deep skillsets in both Grasshopper and Blender. He holds a Bachelor of Fine Arts in Industrial Design from Brigham Young University. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

OrganizationVARIANT3DPresenter:Will SamosirKnit Everything: Surfaces, Systems, and the Future of TextilesPresentation AbstractWhat if anyone who can draw could knit?VARIANT3D exists to break down the barriers to textile manufacturing. Our proprietary software LOOP is the first and only WYSIWYG CAD system for knitting that requires zero knowledge about how knitting works.Unlike conventional knit engineering, which demands months of expert iteration, LOOP lets anyone access a vast library of knit structures and generate machine-ready files in minutes, bringing industrial complexity down to a creative interface. From instant prototyping to scalable product lines, our platform also supports automated calibration and grading. In a world saturated with cut-and-sew fabrics, we’re pioneering a decentralized, on-demand, and zero-waste model of textile production.Beyond that, we recognize that knitting is a medium that blends the language of computation, powerfully soft and flexible materials, as well as pure, collaborative human ingenuity. At VARIANT3D, we’re not just building tools—we’re also cultivating a new language for textile and material innovation. We are excited to share how this vision has shaped our process and journey as an organization, and how we are empowering the future of textiles.Speaker BioWill Samosir is the CTO and Co-Founder of VARIANT3D, where he champions a future that is expressive, adaptive, sustainable, and open. He leads a multidisciplinary team and spearheaded the development of LOOP, a state-of-the-art software platform that reimagines how textiles are made—and who gets to make them. His life’s work is rooted in the belief that humans and computers are co-authors, and that our relationship with complex systems should be intuitive and human-centered.Will is also obsessed with computational geometry, topology, generative design, and emergent behavior. His favorite language is Python, and he’s drawn to all things polymorphic—surfaces, materials, tactile stuff, naming systems, myth and mythology, the many languages of art, and how tools shape thought. He loves music and live shows, and if you’re lucky, you might catch him biking through the summer streets of Brooklyn! This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

OrganizationEaton + Intact SolutionsPresenter:Karthik Rajan VenkatesanNeel KumarAccelerating Metal-to-Plastic Conversion with AI, Implicit CAD, and Mesh-Free SimulationPresentation AbstractThis work presents a simulation-driven generative design framework for reengineering a metallic explosion-proof enclosure into a lightweight, injection-molded fiber-reinforced plastic alternative. The methodology integrates advanced process and performance simulations with AI-guided optimization to enable rapid, intelligent design iteration.Central to this workflow is the use of implicit CAD modeling in nTop, which allows for highly flexible and parameterized geometry generation, seamlessly integrated with a robust, mesh-free simulation engine from Intact Solutions. This combination eliminates traditional meshing bottlenecks and enables direct evaluation of complex geometries without meshing or format conversion.The workflow is executed in two stages. Stage I establishes baseline using Moldflow for plastic flow simulation, Digimat for fiber orientation mapping, and ABAQUS for traditional FEA, culminating in a stress field point cloud. Stage II transitions to an AI-driven design space exploration loop, where models are trained and evaluated through a Bayesian optimization framework. The implicit CAD models are directly analyzed using Intact.Simulation for Automation without any manual pre-processing, enabling a seamless feedback loop between design and performance while supporting rapid, large-scale design iterations.This approach exemplifies the power of computational design at scale—reducing turnaround time from over 48 hours with traditional CAD and FEA methods to under 1.5 hours with the full AI-driven pipeline with implicit modeling and automated, mesh-free simulation.Speaker BioKarthik Venkatesan is a Lead Engineer in Computational and Digital Product Development at Eaton’s Center for Materials & Manufacturing Innovation in Southfield, Michigan. His work focuses on bridging advanced simulation, AI, and generative design to accelerate the development of next-generation engineered systems. Karthik leads R&D initiatives that span simulation-driven design automation, lightweighting, and digital workflows for both traditional and additive manufacturing (AM) processes.He holds a Ph.D. in Mechanical Engineering from Arizona State University, where he led multiscale modeling efforts for composite materials under DoD- and industry-funded programs. His broader research spans geometry compensation for binder jet AM, performance prediction for polymer extrusion-based AM, virtual design of experiments, and generative AI for material discovery.Karthik is also passionate about computational creativity, with interests spanning astro photography, AI-generated media, and music production This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Organization:NovineerPresenter:Dr. Ali TamijaniSimulation and Optimization for FFF/FDM Printed PartsPresentation AbstractAdditive manufacturing with FFF/FDM 3D printing has long struggled to optimize toolpaths for better structural performance. Traditional slicing software failed to fully take advantage of material anisotropy, missing opportunities to boost strength and stiffness. Novineer’s toolpath optimization software changes this by maximizing material properties through tailored print paths based on load paths, resulting in a 60% increase in structural stiffness without changing the geometry.Speaker BioDr. Ali Tamijani, the co-founder/CEO of Novineer, is a professor of Aerospace Engineering at ERAU. He has spent three summers at Air Force Research Laboratory (AFRL) as a Faculty Fellow to explore the structural load paths and load flow. This was followed by investigating a Load Path-based Topology Optimization funded by the Air Force Office of Scientific Research (AFOSR)-Young Investigator Program (YIP). Ali is also working on Multiscale Optimization of Additively Manufacturable Cellular Microstructures that received the National Science Foundation (NSF) -CAREER.RECENT INTERVIEWS & ARTICLES* Call for Speakers: CDFAM Barcelona – April 8–9, 2026Flexcompute: Real-Time Computer-Aided OptimizationAcoustic-Driven Computational Design: Premium Branded Audio In The Automotive Industry – Austin Mitchell – Harman InternationalSimulation and Optimization for FFF/FDM Printed Parts – NovineerEngineering Intelligence- Sergey Pigach – CORE studio | Thornton TomasettiAutomating Design Workflows for 3D Concrete Printed Freeform Staircases – Philip Schneider + Timo Zollner This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:Alloy EnterprisesPresenter:Ryan O’HaraShaping Flow: Computational Design Strategies for High-Performance Liquid Heat ExchangersPresentation AbstractAt Alloy Enterprises, we combine traditional CAD, implicit geometry modeling, and advanced simulation workflows to engineer high-performance cold plates tailored to the unique thermal and dimensional requirements of each customer. Our approach begins with a curated library of optimized, periodic internal geometries that serve as a foundation for thermal performance and manufacturability. Using computational design tools, we scale and adapt these geometries through parametric controls and implicit modeling techniques, enabling rapid customization across a wide range of form factors. Simulation-driven iteration ensures that each design meets target pressure drop and heat transfer criteria before it reaches the build stage. This integrated workflow allows us to balance design flexibility, performance, and production efficiency in delivering scalable liquid heat exchangers for demanding applications.Speaker BioI am a results-oriented business development leader with over 20 years of DoD acquisition experience. I have extensive experience in advanced manufacturing, aerospace engineering, and federal contracting. I have a proven track record of driving significant revenue growth and securing substantial funding through strategic proposals and federal contracts. With expertise in technical hardware and software sales, I enable cross-functional collaboration in aerospace application development. My technical experience includes transitioning research and development activities from concept to full-scale production, leveraging advanced design and manufacturing concepts. I have demonstrated success in initiating and developing processes, including the certification of materials, equipment, and procedures that comply with aerospace and maritime standards. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/Organization:C-InfinityPresenter:Sai NelaturiAssembly Configuration SpacesPresentation AbstractAll non-trivial hardware products are assembled. They are also designed and manufactured in multiple configurations to serve diverse customer needs. Product designs define a configuration space of options that can be instantiated into variants per customer order. OEMs seek to maximize reuse of subassemblies across this space to balance flexibility with cost efficiency—especially in high-mix, low-volume manufacturing.The challenge is translating a product’s design structure into its assembly process structure: reframing design intent as a sequence of operations executed on the factory floor. In Product Lifecycle Management (PLM) terms, this is the translation from the Engineering Bill of Materials (EBOM, “as-designed”) to the Manufacturing Bill of Materials (MBOM, “as-planned”). EBOM and MBOM are not separate domains, but dual representations of the same configuration. Today this translation is manual and painful.At C-Infinity we are automating this translation and building assembly configuration spaces as a foundation for product design and manufacturing planning. By treating EBOM and MBOM as dual views of one structured space, we strengthen reuse, change propagation, streamline configuration management, and enable tighter digital-to-physical integration—addressing long-standing challenges at the heart of advanced manufacturing competitiveness.Speaker BioPh.D. Mechanical Engineering, UW-Madison. Expert in CAD, AI, and Digital Manufacturing. Former R&D Director at Carbon and PARC. DARPA and UW career award recipient. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/OrganizationCarbonPresenter:Andrew SinkPodium Performance: The Future is PersonalPresentation AbstractIn this presentation, learn how world-renowned saddle manufacturer, fizik, has embraced the latest in computational design, customization automation and advanced manufacturing to offer cyclists– from amateur to elite– a one-of-a-kind 3d printed saddle, tuned to their specific needs.The One-to-One saddle leverages each partner’s expertise– fizik’s dedication to saddle craftsmanship, Carbon’s groundbreaking lattice design automation and printing technology, and gebioMized’s dynamic pressure mapping precision– to create a saddle that is not only tuned to custom to each rider, but is also fit for champions. In 2025, Tadej Pogačar rode victorious over the Tour de France finish line on a fully custom One-to-One saddle.But podium performance isn’t achieved overnight. In this presentation, we’ll share how we worked to identify the base saddle geometry, developed robust stress testing, and built a custom pipeline to produce this groundbreaking custom bike saddle at scale.Speaker BioAndrew Sink is a Senior Applications Engineer at Carbon and is currently focused on enabling companies to create the next generation of production 3D printed parts at scale. An enthusiastic voice in the additive manufacturing industry, Andrew is always excited to talk about what the future holds for this technology.In addition to his work at Carbon, Andrew has written and published software tools that are designed for home and hobbyist 3D printing as well as various technical guides and videos related to additive manufacturing. After graduating from the University of South Florida with a degree in Technical Communications, Andrew has had feature articles published in traditional print media and has also created a YouTube channel focused on 3D printing that currently has a view count of over 9.5 million. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com

Recorded at CDFAM Computational Design Symposium, NYC, October 29-30, 2025https://cdfam.com/nyc-2025/OrganizationMoon Rabbit Lab X PUMAPresenter:Jesus Marini ParissiRunning Revolution: Computational Design Behind Fast-R NITRO Elite 3Presentation AbstractThe Fast-R NITROTM Elite 3 marks a true performance revolution, combining cutting-edge engineering with data-driven design. As part of the Collaboration with PUMA, Moon Rabbit Lab developed a computational design workflow that integrates digital simulation, biomechanical analysis and advanced optimization techniques that combined different KPI’s of the shoe’s performance before the first prototype was even made.By running several virtual iterations and hundreds of simulation hours, we achieved a 30 % weight reduction alongside a 3.15 % improvement in running economy versus the previous model, gains that translate directly into seconds shaved off personal bests. This approach unites creative engineering, deep knowledge in material science and targeted biomechanical data, with computational design as the central force driving each decision.This case study highlights the power of combining different areas of expertise with computational design at its core. By prioritizing digital testing and optimization, the process reduces errors and minimizes the need for physical prototyping.Beyond footwear, this scalable framework has broad potential across athletic performance products and a wider range of data-driven consumer goods.Speaker BioJesus Marini Parissi is a computational design engineer who merges creative design with advanced engineering methods. He holds a MSc (Master of Science) of Design Engineering from Politecnico di Milano and BSc (Bachelor of Science) in Mechatronics Engineering from Universidad Nacional Autonoma de Mexico, and his portfolio spans performance engineering, consumer goods, automotive product development, and experimental research.He has contributed to global innovation programs like Stanford ME310 and the MIT Design Lab, and worked at Ford Motor Company, earning four patents. He also consulted for brands such as PUMA and Samsung Research America, helping to establish their first Computational Design department.Today, he leads Moon Rabbit Lab, pioneering new frontiers in product development, system optimization, and design research. By fusing imagination with technical expertise, he fosters collaborative innovation and shapes the future of computational design. This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit www.designforam.com