Discover The AI Agency Journey

The AI Agency Journey

The AI Agency Journey

Author: Ibero AI and Belt Course Partners

Subscribed: 2Played: 4Subscribe

Share

© 2026 Ibero AI and Belt Course

Description

This podcast provides lessons learned and perspectives from Operational Excellence consultants, coaches, and leaders on their journey to grow in their careers, start and grow their agency practice, and incorporate Artificial Intelligence into their processes and those of their clients.

Produced by: Sebastian Alonso, from Belt Course (www.beltcourse.com). LinkedIn: https://www.linkedin.com/in/sebastian-alonso-667862249/

Hosted by: Ibero AI and Belt Course partners

- Antonio Rothenbach. LinkedIn: https://www.linkedin.com/in/antonio-rothenbach-99685110/

34 Episodes

Reverse

If you’re a consultant, coach, or thought leader who relies on reputation, referrals, or content to win business, AI is already changing how people find and trust experts.

In this episode, Antonio Rothenbach sits down with Andi Simon, corporate anthropologist, CEO of Simon Associates Management Consultants, and host of On the Brink with Andi Simon, to explore how AI search is reshaping visibility, credibility, and authority.

Search is no longer just about ranking on Google. Today, tools like ChatGPT, Copilot, and Perplexity summarize, recommend, and sometimes decide who the “preferred expert” is before a prospect ever clicks a link.

This conversation dives into:

How AI search actually works today

Why content alone is no longer enough

How AI decides who to trust and cite

The human side of AI adoption and resistance

What consultants can do now to stay discoverable and relevant

This episode is especially relevant for consultants, advisors, and leaders who want to future-proof their visibility as AI becomes the front door to expertise.

Key Topics & Timestamps

(00:00) Why AI is changing how trust and credibility are built

(01:10) Meet Andi Simon and her background as a corporate anthropologist

(05:00) Why humans resist change and how that affects AI adoption

(08:30) How AI search differs from traditional Google SEO

(11:00) How Andi uses AI as a collaborator, not a replacement

(15:00) What makes content discoverable by AI tools

(18:30) FAQs, authority signals, and AI-driven visibility

(22:00) A simple way to test what AI already knows about you

(26:00) Content repurposing as an AI visibility strategy

(30:00) Why leadership and culture determine AI success

(36:00) Final advice for consultants navigating AI-driven change

About the Guest

Andi Simon is a corporate anthropologist, CEO of Simon Associates Management Consultants, award-winning author, speaker, and host of the podcast On the Brink with Andi Simon.

With over two decades of experience helping organizations adapt to major shifts, Andi brings a unique lens to AI adoption by focusing on human behavior, beliefs, rituals, and leadership. Her work helps leaders and organizations see what’s often right in front of them so they can move forward with clarity and confidence.

About the Host

Antonio Rothenbach is the host of The AI Agency Journey and the founder behind Ibero AI and Belt Course. He works with consultants, leaders, and organizations at the intersection of AI, Operational Excellence, and leadership to turn AI from a buzzword into practical business impact.

Resources & Links

Andi Simon on LinkedIn

Simon Associates Management Consultants: https://simonassociates.net

Andi Simon’s books, podcast, and speaking: https://andisimon.com

Antonio Rothenbach on LinkedIn: https://www.linkedin.com/in/antonio-rothenbach-99685110/

Subscribe & Follow

If you enjoyed this episode, subscribe to The AI Agency Journey on your favorite podcast platform and follow along for more conversations with consultants, operators, and leaders navigating AI-driven change.

New episodes explore real lessons learned at the intersection of AI, leadership, and operational excellence.

Guest: Jess Orr – ex-Toyota engineer, former corporate OpEx leader and VP of Operations

Summary: In this episode, Jess and Antonio connect the dots between Operational Excellence and Artificial Intelligence. Jess shares what she learned at Toyota, in a successful divisional OpEx transformation, in a failed enterprise-wide rollout, and later as VP of Operations — and how all of that experience shapes how she thinks about AI today.

The core message:

OpEx and CI professionals are uniquely positioned to lead AI efforts because they already know how to define problems, find constraints, and drive cultural change. Starting with tools — whether it’s Lean tools or AI tools — almost always fails.

Antonio then introduces the concept of AI Business Audits as a structured way for consultants to partner with clients, identify their real bottlenecks, and use AI for brainstorming, solution design, and ROI modeling, instead of jumping blindly into “doing AI.”

3–5 Key Takeaways:

Toyota vs everyone else: Toyota embedded continuous improvement in everyone’s job, while many companies try to bolt on CI through tools without a culture to sustain it.

Tools don’t fix culture. Rolling out 5S, DMS, or even AI tools without leadership alignment and clear “why” leads to shallow adoption and failed transformations.

Consultants as capability builders, not crutches. External consultants are most valuable when they build internal capability and mentor internal champions — not when they become permanent life support.

OpEx + AI is a natural pairing. CI practitioners already know how to map value streams, find constraints, and run structured problem solving. AI simply gives them superpowers if used correctly.

AI Business Audits are the bridge. Starting from constraints and problems, then using AI to explore options and quantify ROI, is a far better path than “Let’s try some AI tools and see what happens.”

Links:

Book an AI Business Audit with Antonio / Ibero AI: https://calendar.app.google/HahxbRKD77n3KiU9A

Connect with Jess on LinkedIn: https://www.linkedin.com/in/jessorr/

Connect with Antonio on LinkedIn: www.linkedin.com/in/antonio-rothenbach-99685110

Podcast show on YouTube: https://youtube.com/playlist?list=PLyVgVZd7jUlpcp4mwtNMbXlv8D_8CB3Ch&si=JI3iG6LZp6gQT7Va

Guest: Dave Rosenberg, Principal at Locked On Leadership

Summary:

In this episode, Dave shares 35+ years of leadership experience—from Navy officer to company president to leadership coach—and how his Radical Accountability framework helps leaders turn disengaged employees into energized contributors. Together, Antonio and Dave explore how AI tools can complement human coaching, fostering self-awareness, delegation, and engagement.

Top 3 Takeaways:

Leadership gaps = business gaps. Most operational problems stem from cultural and leadership breakdowns. Radical Accountability drives engagement. Clear systems, communication, and shared purpose unlock higher performance. AI as a coaching ally. Used right, AI helps structure thinking and reflection without replacing intuition or empathy. Quote: “My mission is to help every team member say ‘Thank God It’s Monday.’ That’s when you know leadership is working.”

🗓️ Book a 20-min AI Business Audit : https://calendar.app.google/y4z3RGmK2n2KHfzMA

Host: Antonio Rothenbach, Founder & CEO of Ibero AI

Guest: Donna Huntley, CEO of People Pulse Ventures Episode

Summary:

Fear is one of the biggest barriers to AI adoption — and it’s costing companies growth, innovation, and talent. In this conversation, Antonio and Donna break down how to replace fear with confidence through training, governance, and culture. Donna shares stories from her 20+ years in HR consulting — from early digital hiring systems to leading change at Accenture — and offers practical strategies for leaders who want to bring AI into their organizations without losing the human touch.

Connect with Donna:

- www.peoplepulseventures.com

- Call/text: 803-836-0306

Connect with Antonio:

- www.linkedin.com/in/antonio-rothenbach-99685110/

Subscribe to The AI Agency Journey Podcast:

- Spotify: https://open.spotify.com/show/0lXZkUqO2RIkN7vTO1C2p7?si=25f17d152e6040e7

- Apple Podcasts: https://podcasts.apple.com/us/podcast/the-ai-agency-journey/id1788580727

Read the blog article here: https://www.beltcourse.com/blog/linkedin-growth-that-lands-ai-opex-ci-clients-without-gaming-the-algorithm A detailed guide for Artificial Intelligence (AI), Operational Excellence (OpEx), and Continuous Improvement (CI) consultants on leveraging LinkedIn for client acquisition. It outlines a strategic playbook for creating content that resonates with B2B buyers, emphasizing observable signals for distribution rather than trying to outsmart the algorithm. Key areas covered include optimizing post engagement, crafting impactful content formats, and using LinkedIn's native features to maximize reach. The guide also offers practical advice on posting frequency, avoiding common mistakes, and measuring success through relevant metrics, aiming to help consultants generate qualified leads and conversations.

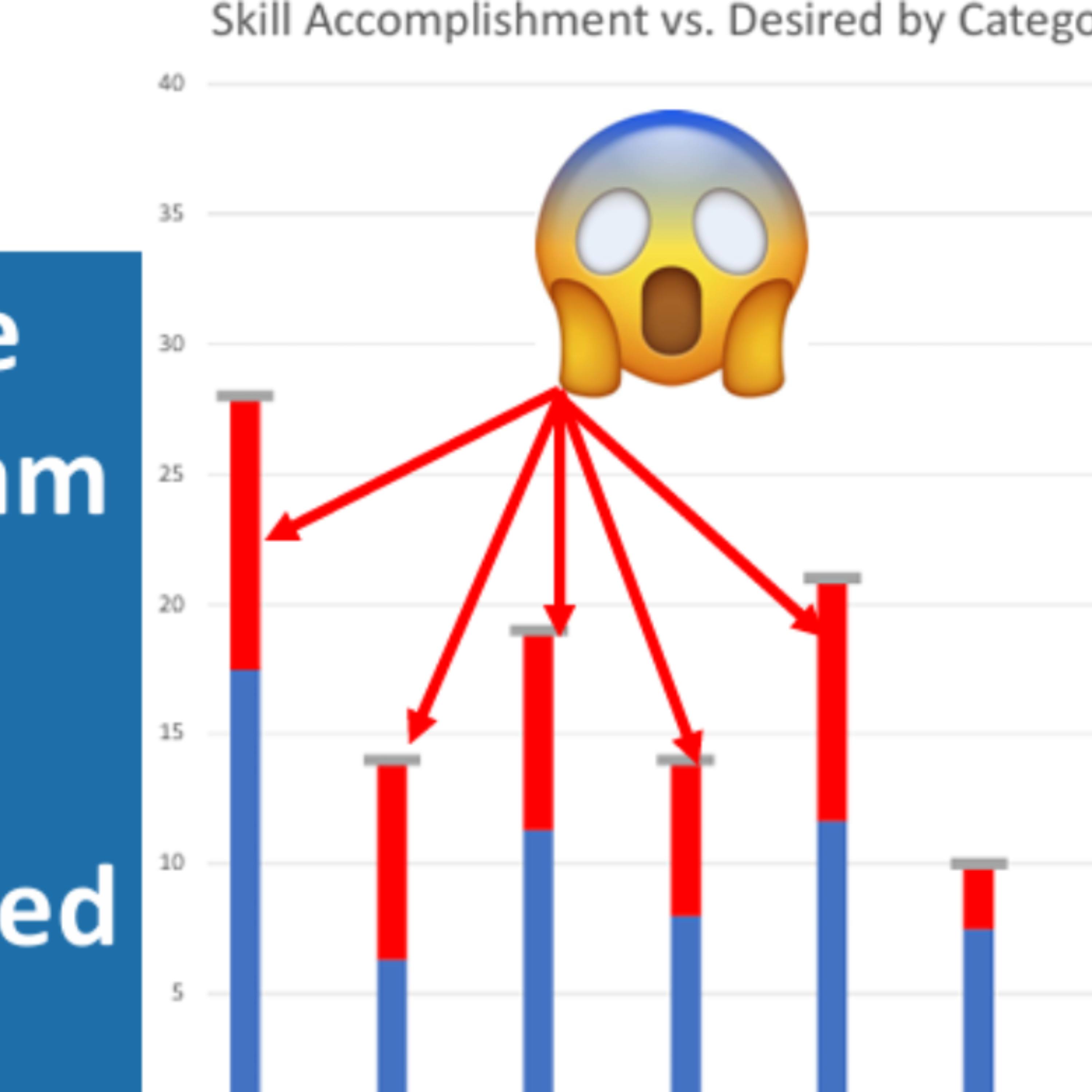

This episode explores the evolving landscape of continuous improvement leadership and identifies significant skill deficiencies across various sectors. It highlights universal gaps in areas like digital transformation leadership and data analytics, while also detailing industry-specific needs for Industrial Advanced (e.g., automotive, medical devices), Industrial (e.g., pharmaceuticals, food & beverage), and Supply Chain professionals. The analysis proposes tailored coaching programs designed to address these gaps, emphasizing technical, leadership, and strategic competencies.

Coaching Programs for Industrial Advanced

Digital Transformation: Transition to lead a Digital and Artificial Intelligence Transformation from start to finish! Click here to learn more.

DMAIC and AI-Assisted Process Improvement: Master the DMAIC methodology and AI-enhanced analytics to become the go-to process improvement leader! Click here to learn more.

Innovation Launch Mastery: Master FMEA, Digital Twins, and Agile Innovation to become the launch leader who delivers on time, on budget, and exceeds expectations! Click here to learn more.

Coaching Programs for Industrial

Achieving Stability (Focus on Stability and Sustainment): Solidify your teams' ability to sustain improvements with the use of control plans, proper communication, report-outs, Layered Audits, and more! Click here to learn more.

A3 Problem-Solving (RCA, First Projects in your A3): lead projects, using A3 Problem-Solving and Job-Specific pathways dependent on your opportunities! Click here to learn more.

Lean Leader: Start using Lean methodologies and tools (VSM, 5S, QCO, TPM, DMS, Kaizen, JIT, Poke Yoke, etc.) to transform your value streams. Click here to learn more.

Kaizen Leader: Be fully prepared to lead a Kaizen Event to make sustainable improvements quickly, without wasted efforts! Click here to learn more.

Coaching Programs for Supply Chain

Digital Transformation: Transition to lead a Digital and Artificial Intelligence Transformation from start to finish! Click here to learn more.

Supply Chain Management (SCM) Leader: Achieve stability and advance into Proactive Supply Chain Management This Year! Click here to learn more.

Strategic Planning (Hoshin Kanri + Value Stream Mapping, Bottleneck, OEE & Loss Analysis): Build your Strategic Plans, aligning goals with resources, without taking years to get better at it! Click here to learn more.

Read the source article here: https://www.beltcourse.com/blog/the-ci-manager-crisis-why-ci-leaders-struggle-and-why-hiring-a-ci-manager-from-outside-isn-t-the-solution

Continuous Improvement (CI) Managers frequently struggle due to issues like team resistance, role ambiguity, and a lack of impact. The author contends that hiring externally is a detrimental solution because it leads to slow ramp-up times, higher costs, and internal team demoralization. Instead, the article advocates for developing internal talent to fill CI Manager roles, emphasizing that individuals already familiar with the organization's culture and processes are better positioned for success. This internal development approach fosters quicker integration and boosts overall team morale and retention, ultimately leading to more effective and sustainable CI initiatives.

Read the article that was the source of this discussion here: https://www.beltcourse.com/blog/why-do-operational-excellence-implementations-fail-in-2024

Learn a better way at www.beltcourse.com

This episode explores why Operational Excellence (OpEx) implementations often fail, identifying a primary issue as a lack of comprehensive capability building rather than solely blaming leadership. It acknowledges the challenges faced by OpEx professionals in providing sufficient training to everyone and examines existing solutions like consultants and outside training providers, highlighting their limitations in cost, practicality, and scope. The author suggests a need for different solutions that leverage the expertise of multiple individuals and provide a structured roadmap for training the right people effectively, with the goal of significantly reducing OpEx failure rates.

For a longer list of specific easy and impactful office project examples for each of the most common areas and functions, find it by clicking here!

Office & Service Companies – 10 Project Ideas per area

Office Functions within Industrial Organizations – 10 Project Ideas per function

The application of Lean in Offices and Service environments is slightly different... learn more about it here... https://www.beltcourse.com/lean-in-offices-and-services-one-pager

This episode explores numerous project ideas for applying Lean methodologies, Operational Excellence principles, and Artificial Intelligence within office and service environments. It categorizes these examples into ten distinct areas for both office and service companies, such as legal, accounting, and marketing, and ten specific office functions within industrial organizations, including engineering, finance, and HR. For each area and function, targeted project concepts are discussed, offering concrete starting points for continuous improvement initiatives. Many examples explicitly mention specific tools like A3 problem-solving, value stream mapping, FMEA, and potential AI applications like automation and prediction. The episode aims to inspire practical application of these concepts for enhancing efficiency and effectiveness in various organizational settings.

Lean and Operational Excellence (OpEx) methodologies, traditionally associated with manufacturing, are highly applicable and beneficial in office and service environments. These principles address common workplace inefficiencies such as lengthy approval processes and redundant tasks by treating offices as "invisible factories" with improvable workflows. By employing tools like process mapping, root cause analysis, and AI-powered insights, organizations can reduce errors, eliminate low-value work, and empower employees.

You have to equips teams with practical skills to implement these improvements, offering real-world examples of successful transformations across various industries. Ultimately, applying Lean and OpEx, often enhanced by AI, leads to significant gains in efficiency, customer satisfaction, and overall organizational performance in non-manufacturing settings.

Join the Office Operational Excellence Program today.

✔️ Explore the Program📄 Download the Full Program Outline

Lean isn’t just for factories anymore—let’s bring it to the office, where it belongs.

The application of Lean in Offices and Service environments is slightly different... learn more about it here... https://www.beltcourse.com/lean-in-offices-and-services-one-pager

For a longer list of specific easy and impactful office project examples for each of the most common areas and functions, find it by clicking here!

Office & Service Companies – 10 Project Ideas per area

Office Functions within Industrial Organizations – 10 Project Ideas per function

Get coached by our AI Assistant OpEx Coach! Link: https://www.beltcourse.com/opex-coaches-ai-assistant

Get your Kaizen Event Planning Checklist here:

https://www.beltcourse.com/opt-in-66aea8d5-aee0-44d8-9b07-95328d6f098a

Get your Kaizen Event agenda template here:

https://www.beltcourse.com/kaizen-event-agenda-template

This episode explains kaizen events by providing various industry-specific examples that illustrate their application in solving different operational problems. Organized by sector like manufacturing, food production, and even airports, each example outlines a problem statement, the steps taken during a kaizen event, and the resulting improvements. The purpose is to inspire readers with relatable scenarios and highlight the versatility of kaizen for continuous improvement. Additionally, the text includes links to further resources and training opportunities.

Blog article here - Kaizen and AI Project Examples in Office and Service Environments.

https://www.beltcourse.com/blog/examples-of-kaizen-events-for-different-types-of-problems

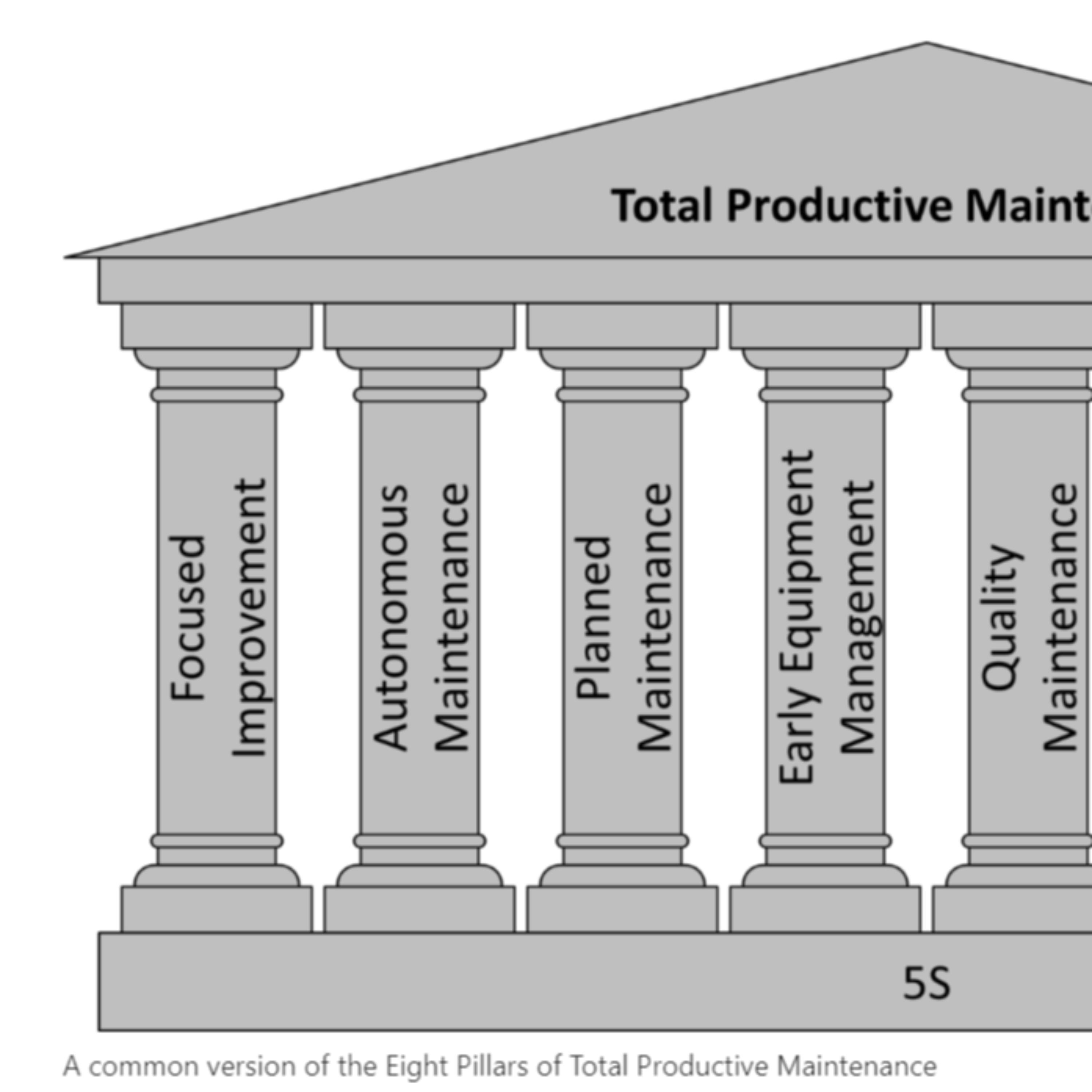

This episode compares various Operational Excellence (OpEx) methodologies, including Six Sigma, Lean, Theory of Constraints, Total Productive Maintenance, World Class Manufacturing, and Agile. It explores reasons for OpEx program failures, emphasizing the importance of integration, culture change, and employee involvement. It highlights the benefits of combining methodologies.

If you'd like to see a chart that outlines the industries, famous companies, key performance indicators (KPIs), strengths, and weaknesses associated with each methodology. check it out here:

You can also look into Belt Course's coaching programs that combine the best of all OpEx methodologies and provides opportunities to become a coach or consulting partner. Learn more at www.beltcourse.com.

Digital transformations often fail due to internal organizational behaviors and psychological factors. Common themes in failed transformations include unrealistic expectations, internal misalignment, and resistance to change. Organizations often lack a clear vision of their future state and over-delegate responsibilities to project teams or technical implementers.

Effective program management and governance are crucial, as is the ability to recognize and mitigate risks early on. Success requires a balanced approach, building internal competencies while leveraging external expertise.

Does it sound a lot like Lean and Operational Excellence Transformations? Maybe these transformations need to be integrated for success, learning from previous failures and building on the strengths of each pathway.

Are you a Tech Industry professional working on transitioning to a role in Industrial or Supply Chain organizations? Or an Industrial Organization leader wishing to advance into a digital transformation?

This program in any language will help you transition to lead a Digital Transformation from start to finish!

Link: https://www.beltcourse.com/digital-transformation-program

Assess your OpEx Champion & Sponsor skills here!

https://www.beltcourse.com/opex-champion-sponsor-skills-assessment-access

Get your own customizable OpEx Deployment A3 here:

https://www.beltcourse.com/opt-in-06eaf5f1-6189-499e-990a-12a31f011fb1

The episode discusses the crucial role and function of steering committees within organizational improvement initiatives in the context of lean transformations, highlighting their importance in providing leadership alignment and guidance to lean facilitators. Their responsibilities include strategic decision-making, resolving escalated issues, and ensuring projects stay on track with resources and budget. World Class Manufacturing (WCM), a comprehensive methodology for achieving operational excellence through managerial and technical pillars, requiring top management involvement and continuous improvement efforts.

Learn more about WCM in this blog article that gathers the best resources in one place.

What is WCM (World Class Manufacturing) - Pillars and Structure Overview. Link: https://www.beltcourse.com/blog/world-class-manufacturing-wcm-explained-in-detail

World Class Manufacturing (WCM) is a comprehensive methodology that integrates Lean principles, Total Productive Maintenance, and Total Quality Management to foster continuous improvement and eliminate waste. It features 10 managerial and 10 technical pillars, each with steps for reactive, preventive, and proactive phases, offering a structured approach to operational excellence adaptable across industries. Successful implementation requires top management commitment, a clearly defined plan, and continuous employee development. WCM emphasizes waste elimination, efficiency, quality improvements, cost savings, and sustainable practices, undergoing regular audits to assess its effectiveness. Customization is encouraged to align with specific organizational structures, facilitated by dedicated teams with leaders experienced in their respective areas. The goal is to drive cultural change, making WCM an integral part of every employee's role, as supported by resources and training programs.

This episode explores the JIPM TPM Award, which recognizes excellence in Total Productive Maintenance, emphasizing structured pillars and lean tools. It highlights its comprehensive structure that uses checklists and pillars. The piece details the award process, benefits such as growth and cost reduction. However, it also critiques the award's shortcomings, such as a "checklist" mentality that may misdirect resources and its failure to evolve with modern business trends like Digital Transformation. The article suggests companies should evolve TPM instead of rigidly pursuing an outdated award system, referencing World Class Manufacturing as an attempt at modernization.

The affiliative leadership style, emphasizing harmony and strong relationships within a team. It defines the style's core elements, such as a people-first approach, strong morals, and positive communication. The video details the advantages of this style, including improved morale and conflict resolution, while also addressing its weaknesses, like overlooked underperformance and avoidance of constructive criticism. It emphasizes the importance of using this style in conjunction with others, and offers advice on implementing affiliative techniques while mitigating potential negative outcomes. The overall goal is to guide leaders in fostering positive team environments while still achieving organizational objectives.

Course Forward:

Consider sharing with others to understand why TPM is more comprehensive than just Maintenance, just at one Site, or just in Operations.

And if you'd like to learn more about TPM or WCM (WCM is an evolution of TPM which attempts to modernize TPM and add other managerial pillars and technical pillars which were a gap in TPM), please visit our blog sections...

TPM: https://www.beltcourse.com/blog?tag=total+productive+maintenance

WCM: Note there will be a lot of overlapping articles, but that will help you also see the similarities and differences between TPM and WCM. https://www.beltcourse.com/blog?tag=total+productive+maintenance

TPM aims to maximize equipment effectiveness through comprehensive employee involvement. It seeks to transform the mindset from reactive repairs to proactive care, treating equipment as if it were brand new. This involves teamwork, skill development, and a focus on machine stability and availability. TPM strives for zero breakdowns and losses through strategies like autonomous maintenance and planned maintenance. The system focuses on addressing hidden defects and fostering a healthier company culture by prioritizing equipment health, comparing it to personal health. TPM implementation includes eight key strategies with a focus on the reality of broken machines. The approach encourages an aspirational zero-tolerance for breakdowns, similar to safety and quality goals.

Join Belt Course as a Coach here: https://www.beltcourse.com/join-us-as-a-coach

And consider becoming a Partner here: https://www.beltcourse.com/becomeapartner

Check out Belt Course's Simulation Calendar here: https://www.beltcourse.com/simulations-calendar

Guidance on pursuing a career in Continuous Improvement (CI) consulting. It explores the role of a CI consultant, emphasizing the need to guide clients through improvement processes using appropriate tools. The speaker outlines two primary paths: joining a consulting agency directly or gaining experience through a corporate CI team. The video highlights the pros and cons of each route: agencies offer broader exposure and structured learning but may prioritize sales, while corporate roles provide in-depth experience within a single organization, but can result in a limited understanding of the discipline. The video stresses the importance of analytical skills, change management, and practical implementation expertise for success in the field, and stresses the importance of making change happen by also taking the people involved along the CI journey.

On this episode, we explore why and how the Visionary Leadership style (one of Goleman's 6 Leadership Styles based on Emotional Intelligence) can be used in an Operational Excellence setting. Whether it's in a turnaround, a startup, or Hoshin Kanri, you'll learn about its benefits and limitations.

To learn more about Leadership in an Operational Excellence setting, visit our blog at https://www.beltcourse.com/blog?tag=leadership