Porsche Engineers Just Solved a Problem Most Carmakers Didn’t Know Existed

Description

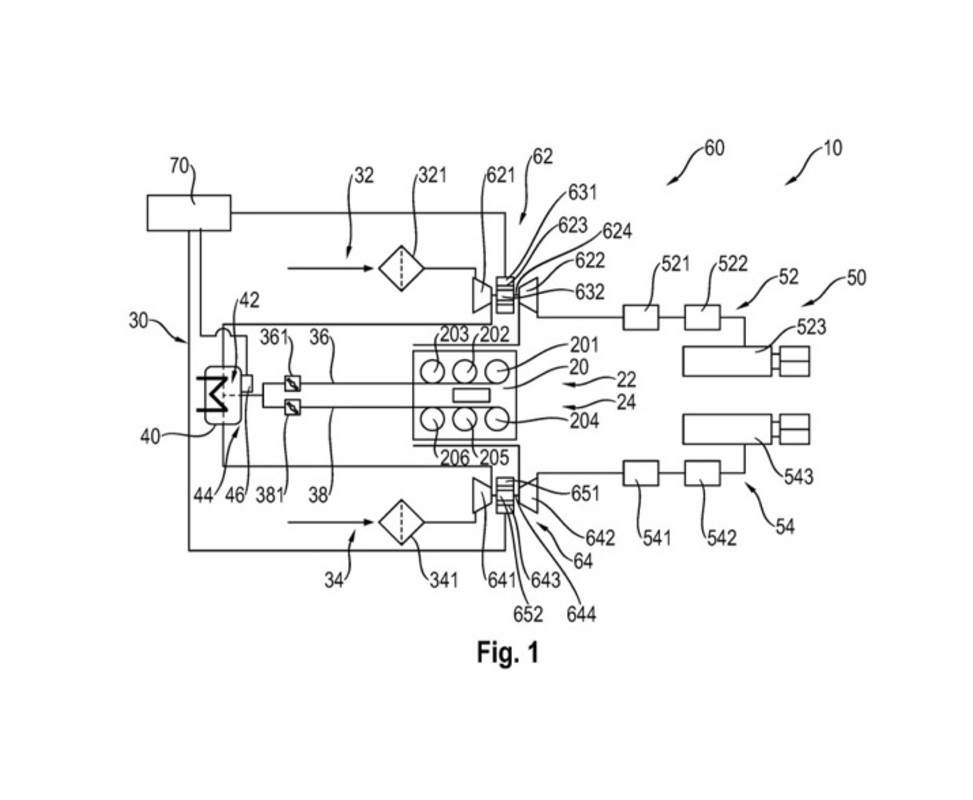

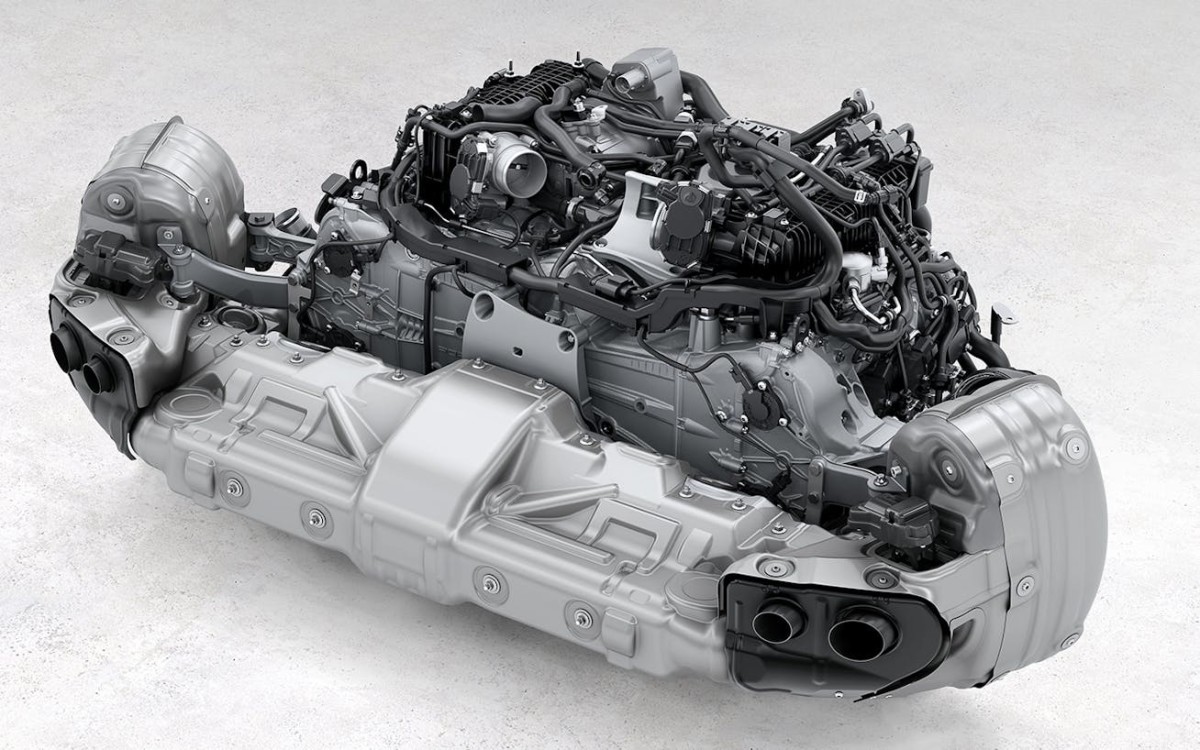

Porsche revealed its first electric-assisted turbocharger, dubbed the T-Hybrid, in the new 911 GTS launched in May this year. An electric motor sitting within the sole large turbocharger allows it to spool up instantly rather than having to wait for revs and exhaust gas pressure to build, thus eliminating turbo lag.

Fast forward to last month and the Stuttgart-based automaker unveiled their most powerful production 911 yet, the 992.2 Turbo S that pumps out an eye-watering 701 horsepower from its 3.6-litre flat six — this time equipped with twin turbochargers featuring the T-Hybrid system. In light of these developments, you would think that Porsche’s engineers may be due a break to pat themselves on the back, however nothing could be further from the truth. A recent patent discovered by CarBuzz and filed with the German Patent and Trade Mark Office (DPMA) indicates that Porsche is already gearing up to further refine its latest creation and take it to the next level.

<figure>

<figcaption>

DPMA

</figcaption></figure>

The Issue With Twin Turbos

Porsche engineers are now working on overcoming a common issue with parallel twin turbos that feed two cylinder banks through a shared intake plenum — unequal airflow from each turbo. In such a setup, air pressure is conventionally measured by a mass air flow (MAF) sensor in the shared plenum to monitor the total air entering the engine, with no way to accurately track the airflow from each turbo individually.

Ideally, the amount of air coming from each turbo should be the same; however, intake valve pulses, temperature variations, and other variables can lead to interruptions in the airflow to either bank. The resultant imbalance in boost pressure may present as a flat spot, inconsistent power delivery, and in extreme cases, cause flow stall. This is when hot air flows in the wrong direction, back towards the intake, and can lead to catastrophic damage to the turbos, components in the intake area, and even the engine.

<figure>

<figcaption>

Porsche

</figcaption></figure>

Porsche T-Hybrid Turbo Technology Explained

While the chances of flow stall occurring in modern engines are extremely slim, Porsche engineers aren’t taking any chances. The T-Hybrid system described in the new patent employs the electric motors within each turbocharger to offer a clever fix for flow stall. When the MAF sensor detects a pressure drop that signals airflow disruption, the engine management system immediately cross-checks turbo speeds. If one or both turbos are slowing due to reverse pressure, the electric motors instantly spin them back up to restore airflow and stabilize intake pressure across both banks.

The result is seamless torque delivery, with each turbo able to correct itself independently using its in-built electric motor. The patent in question outlines a six-cylinder engine with two banks; however, the system can be adapted and scaled to any engine with a pair of parallel turbos that feed two cylinder banks through a shared intake plenum.

While Porsche’s new hybrid turbocharger technology seems like a great way to keep turbo lag at bay, employing the electric motors to also ensure intake pressure equilibrium across both banks in a twin turbo setup is pure genius.