From 4 to 140: What Building Northvolt’s Digital Core Taught Anton Melander About Scaling and Starting Over

Description

📣 A quick reminder before we start: Our next ITOT.Academy kicks off on January 23, and our early bird offer is still available. Do you want to join our third group and learn how to bridge IT and OT? There is no better time than now! 👉 Check the curriculum on ITOT.Academy or in this previous article.

When Anton Melander joined Northvolt in 2018, the company had around 100 employees and zero factories. The goal? Build Europe’s first large-scale lithium-ion battery production from scratch — and do it fast.

“When I joined, there was nothing. I joined the digitalization department, which at the time was me and three others,” Anton told us. “We knew making batteries was fast — really fast — and with tight tolerances. Even microns of misalignment could lead to short circuits. So we wanted to be as data-driven as possible when scaling production.”

From that tiny team, Northvolt’s digitalization function grew to over 140 people, while the company itself ballooned to 5,000 employees. It’s a rare story (and one that ended too soon, after Northvolt’s bankruptcy earlier this year). But in those years, Anton learned what it truly means to build an OT organization from nothing, and why many of those lessons are now shaping his next chapter as a startup founder.

Thanks for reading The IT/OT Insider! Subscribe for free to receive new posts and support our work.

Greenfield Decisions

Northvolt’s early advantage was also its biggest challenge: a completely blank slate.

“We had to figure out what to build and what to buy,” Anton said. “Off-the-shelf software meant long requirement lists, consultants, and change orders. Building in-house gave us flexibility, but it also meant taking full ownership.”

At the time, OPC UA was only beginning to gain traction. Northvolt pushed its equipment suppliers to provide compliant servers and built its own IoT platform to handle the data. “We provisioned over a thousand gateways,” Anton recalled. “Just setting that up was a project in itself.”

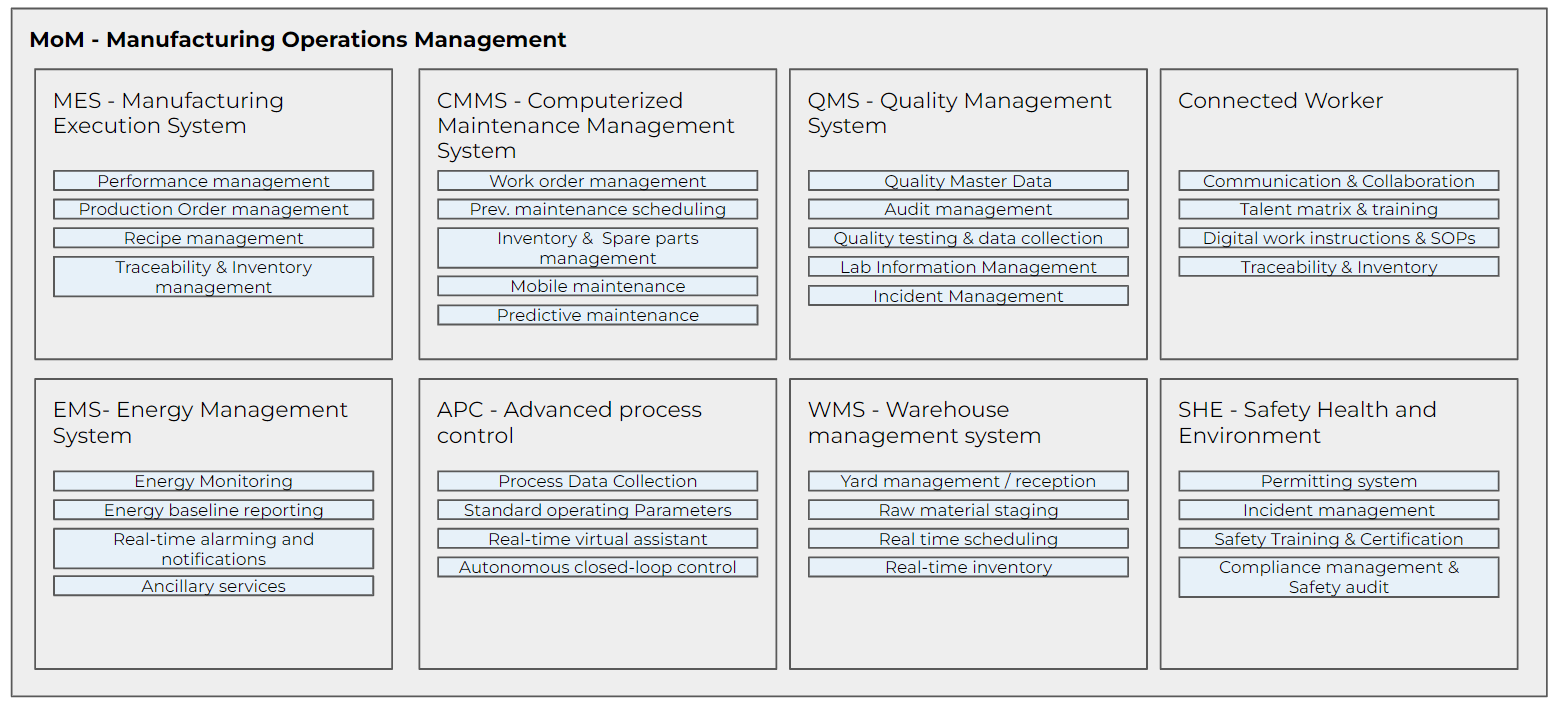

That internal platform became the backbone of production — the foundation of what they later called North Cloud, an internal MES connecting operations, quality, and material flow. “We built a lot ourselves,” Anton said, “but we still leveraged AWS for the cloud, and bought things like ERP and PLM. It was a mix, but a deliberate one.”

From Projects to Products

As production ramped up, the company’s digital organization had to evolve.

“In the beginning, we were completely project-based,” Anton explained. “But as production started, we realized that technology is one thing — it’s only useful if it actually helps people do their job. So we moved from a project-oriented way of working into a product-oriented one.”

That shift (which many IT/OT teams wrestle with) required a mindset change. “Everyone wants their feature,” he said. “The backlog keeps growing forever. But not everything that sounds important actually moves the needle. You need to tie initiatives to measurable results: quality, throughput, yield.”

He laughs looking back. “Sometimes senior stakeholders would say, ‘This is the most important thing,’ and you had to tell them: ‘It’s not going to increase throughput or quality.’ That’s the hard part.”

His other big lesson? Master data.

“You can’t calculate OEE if you don’t know the ideal cycle time. You can’t calculate downtime if you don’t know the planned uptime. It’s easy to draw perfect architecture diagrams, it’s harder to make them work in practice.”

What Comes After Northvolt

Anton left Northvolt in 2023, before its final collapse, but the experience left him with two realizations: first, that building your own tech stack is both empowering and costly and second, that most manufacturers will never have that luxury.

“More than 90 percent of manufacturing companies have fewer than 200 employees,” he said. “They can’t hire 140 people to build their own MES or IoT platform. And yet, they still need data.”

That insight became the starting point for his new company, Ronja, which focuses on helping small and mid-sized manufacturers make sense of the data they already have.

“We’ve spoken to more than 300 manufacturers since we started,” Anton told us. “Almost all of them say the same thing: they have lots of data, but they’re not using it. The problem isn’t collecting data, it’s getting value out of it.”

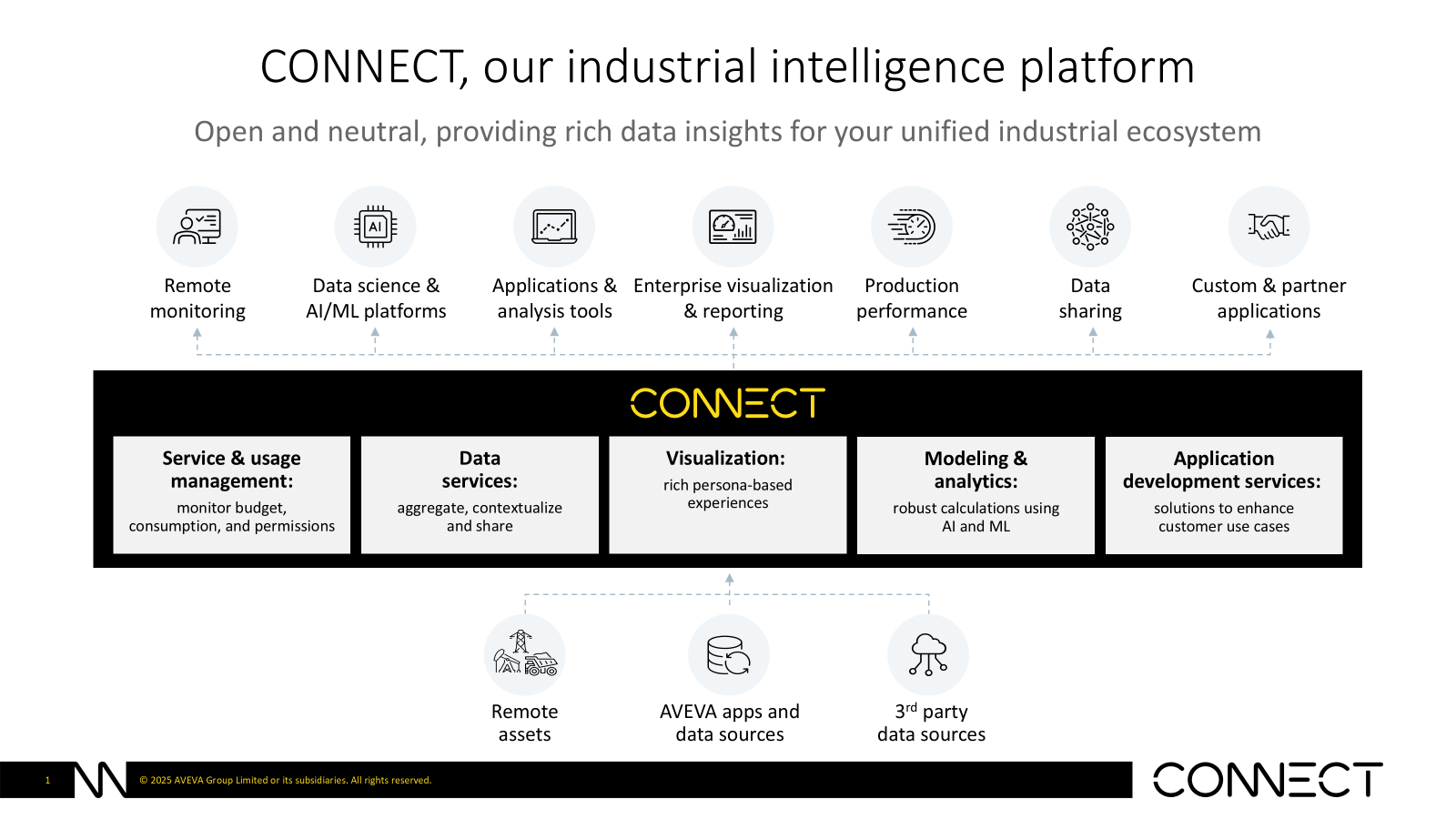

Ronja’s approach isn’t to replace systems, but to sit on top of what exists, making data accessible to non-technical users. “In most factories,” he said, “data lives in Excel, in emails, in historians. We help people connect it, visualize it, and analyze it faster — without waiting for a two-year MES rollout that eats the entire budget.”

Closing Thoughts

Northvolt’s story is one of ambition and hard-earned lessons: a company that built everything from scratch, scaled fast, and still couldn’t outrun industrial reality. But its alumni, like Anton, carry those lessons forward.

His takeaway applies to anyone working on digital transformation, from startups to global enterprises:

“The closer you are to the shopfloor, the more unique every factory becomes. You can’t standardize everything — but you can make it easier to understand, to learn, and to improve.”

And that, ultimately, is what industrial digitalization has always been about.

Stay Tuned for More!

Subscribe to our podcast and blog to stay updated on the latest trends in Industrial Data, AI, and IT/OT convergence.

🚀 See you in the next episode!

Youtube: https://www.youtube.com/@TheITOTInsider Apple Podcasts:

Spotify Podcasts:

Disclaimer: The views and opinions expressed in this interview are those of the interviewee and do not necessarily reflect the official policy or position of The IT/OT Insider. This content is provided for informational purposes only and should not be seen as an endorsement by The IT/OT Insider of any products, services, or strategies discussed. We encourage our readers and listeners to consider the information presented and make their own informed decisions.

This is a public episode. If you would like to discuss this with other subscribers or get access to bonus episodes, visit itotinsider.substack.com