Mission Partnerships in UK Defence: How to make them work

Update: 2025-11-21

Description

Introduction: Defence as an engine for growth

The government's Defence Industrial Strategy 2025 (DIS25) is clear that "business as usual" in procurement is no longer an option. Defence has been placed at the heart of the UK's modern industrial strategy, identified as one of eight priority sectors to drive economic growth and resilience.

The strategy is frank in its diagnosis of the current system's weaknesses. Defence investment and economic strategy remain misaligned. Procurement processes have failed to adapt to an era where emerging technologies are reshaping warfare faster than at any point in living memory. Structural inefficiencies - from misaligned incentives to poor competition and weak exports - have left the UK industrial base struggling to deliver at the pace and scale required.

DIS25 calls for something different: procurement that reduces waste, accelerates innovation, empowers SMEs, and crowds in private capital. It seeks to create a vibrant defence technology ecosystem, one where delivery is faster, risk is shared more equitably, and capability can spiral forward through rapid increments. The ambition is to transform the relationship between government and industry, so that defence becomes not just a consumer of technology but a driver of economic productivity.

This context sets the stage for the idea of "mission partnership." The term is gaining currency across defence, but its meaning remains contested. At its best, it represents a practical shift in how programmes are delivered: a relationship structure where incentives, accountability and behaviours are aligned to outcomes. At its worst, it risks becoming a hollow buzzword, a softer synonym for "contractor" that re-badges old models without changing the fundamentals.

The question this paper explores is whether mission partnerships can provide the practical vehicle through which the ambitions of DIS25 are realised. It argues that they can, but only if approached seriously: as a means of reshaping delivery behaviours, not simply as a new label for old practices.

Why the system struggles today

The weaknesses identified in DIS25 are not new. They are the product of decades of choices and cultural habits that have left the system ill-suited to today's demands.

Policy pressure for pace, but institutional drag. Ministers have repeatedly signalled the need for faster delivery. The Integrated Procurement Model (IPM) commits Defence to deliver major equipment programmes within five years and digital programmes within three - targets that would have been unthinkable even a decade ago. Yet the approvals and governance cycles underpinning procurement remain rooted in Cold War-era timelines.

Churn widens the knowledge gap. High turnover across MOD, particularly in technical and engineering roles, erodes institutional memory. Programmes lose continuity, forcing new teams to relearn the same lessons and repeat the same mistakes. This constant rotation undermines trust between customer and supplier, creating a public-private knowledge gap that grows wider with every cycle.

Outsourcing legacies and switching costs. Two decades of outsourcing have left Defence dependent on a limited set of suppliers. Relationships have become brittle, with high switching costs that make even obvious changes operationally risky. Far from creating a competitive marketplace, outsourcing has often entrenched incumbents, leaving government hostage to long-term contract dependencies.

Blurry boundaries and accountability. Too many programmes begin with contract mechanics rather than mission outcomes. Assurance is treated as paperwork to be satisfied, not as a shared responsibility for safety and performance. The result is a culture where suppliers do what the contract says, not what the mission requires.

The combined effect is predictable: while policy demands agility and tempo, the system continues to generate delay.

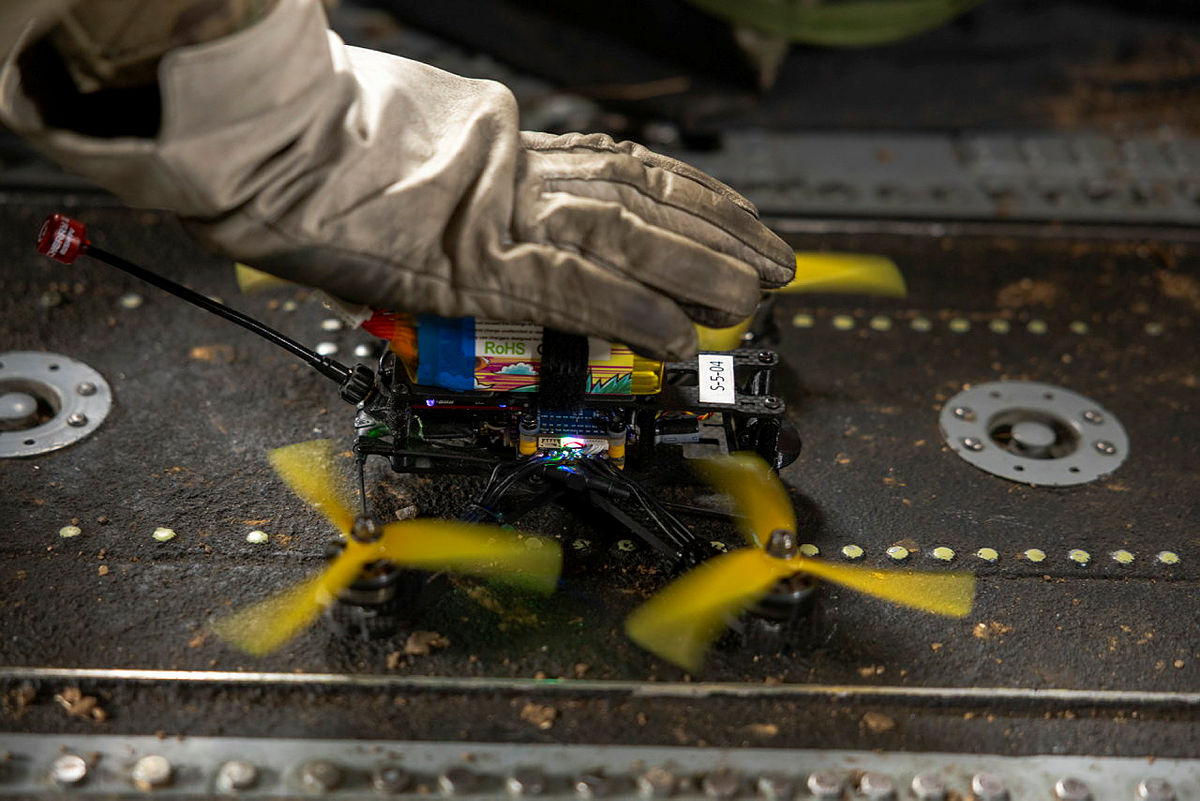

A shifting moment in defence innovation

The environment, however, is shifting. T...

The government's Defence Industrial Strategy 2025 (DIS25) is clear that "business as usual" in procurement is no longer an option. Defence has been placed at the heart of the UK's modern industrial strategy, identified as one of eight priority sectors to drive economic growth and resilience.

The strategy is frank in its diagnosis of the current system's weaknesses. Defence investment and economic strategy remain misaligned. Procurement processes have failed to adapt to an era where emerging technologies are reshaping warfare faster than at any point in living memory. Structural inefficiencies - from misaligned incentives to poor competition and weak exports - have left the UK industrial base struggling to deliver at the pace and scale required.

DIS25 calls for something different: procurement that reduces waste, accelerates innovation, empowers SMEs, and crowds in private capital. It seeks to create a vibrant defence technology ecosystem, one where delivery is faster, risk is shared more equitably, and capability can spiral forward through rapid increments. The ambition is to transform the relationship between government and industry, so that defence becomes not just a consumer of technology but a driver of economic productivity.

This context sets the stage for the idea of "mission partnership." The term is gaining currency across defence, but its meaning remains contested. At its best, it represents a practical shift in how programmes are delivered: a relationship structure where incentives, accountability and behaviours are aligned to outcomes. At its worst, it risks becoming a hollow buzzword, a softer synonym for "contractor" that re-badges old models without changing the fundamentals.

The question this paper explores is whether mission partnerships can provide the practical vehicle through which the ambitions of DIS25 are realised. It argues that they can, but only if approached seriously: as a means of reshaping delivery behaviours, not simply as a new label for old practices.

Why the system struggles today

The weaknesses identified in DIS25 are not new. They are the product of decades of choices and cultural habits that have left the system ill-suited to today's demands.

Policy pressure for pace, but institutional drag. Ministers have repeatedly signalled the need for faster delivery. The Integrated Procurement Model (IPM) commits Defence to deliver major equipment programmes within five years and digital programmes within three - targets that would have been unthinkable even a decade ago. Yet the approvals and governance cycles underpinning procurement remain rooted in Cold War-era timelines.

Churn widens the knowledge gap. High turnover across MOD, particularly in technical and engineering roles, erodes institutional memory. Programmes lose continuity, forcing new teams to relearn the same lessons and repeat the same mistakes. This constant rotation undermines trust between customer and supplier, creating a public-private knowledge gap that grows wider with every cycle.

Outsourcing legacies and switching costs. Two decades of outsourcing have left Defence dependent on a limited set of suppliers. Relationships have become brittle, with high switching costs that make even obvious changes operationally risky. Far from creating a competitive marketplace, outsourcing has often entrenched incumbents, leaving government hostage to long-term contract dependencies.

Blurry boundaries and accountability. Too many programmes begin with contract mechanics rather than mission outcomes. Assurance is treated as paperwork to be satisfied, not as a shared responsibility for safety and performance. The result is a culture where suppliers do what the contract says, not what the mission requires.

The combined effect is predictable: while policy demands agility and tempo, the system continues to generate delay.

A shifting moment in defence innovation

The environment, however, is shifting. T...

Comments

In Channel